Table of Contents:

- Find the Right Compression Spring with Spring Finder 5.0

- #Key-Features-of-Spring-Finder-5.0

- How to Use Spring Finder 5.0

- #Tips-for-Maximizing-the-Use-of-Spring-Finder-5.0

- How to Measure your Compression Spring for the Correct Search

- Benefits of Using Spring Finder 5.0

- Designing Custom Springs with Spring Creator 5.0

- Key Features of Spring Creator 5.0

- Benefits of Using Spring Creator 5.0

- Conclusion

Spring Finder 5.0, developed by Acxess Spring, is specifically designed to cater to the needs of engineers, designers, and purchasing agents who require an efficient and reliable method to select compression springs for various applications. The Spring Finder 5.0 tool simplifies the complex process of identifying the correct spring by offering a user-friendly interface and a robust database of potential options. This means you can find springs that meet very specific requirements without manually sorting through catalogs or extensive product lists, saving both time and resources.

- Extensive Search Parameters: The tool allows you to specify a wide range of search parameters including outer diameter, length, wire diameter, and load requirements. This granularity helps in pinpointing the exact spring among millions of options that fit your application requirements, thereby reducing the risk of component failure due to mismatched specifications.

- Real-Time Results: As you adjust the search criteria, Spring Finder 5.0 dynamically updates the results. This immediate feedback allows you to fine-tune your specifications without the need to restart the search, enhancing the efficiency of the selection process.

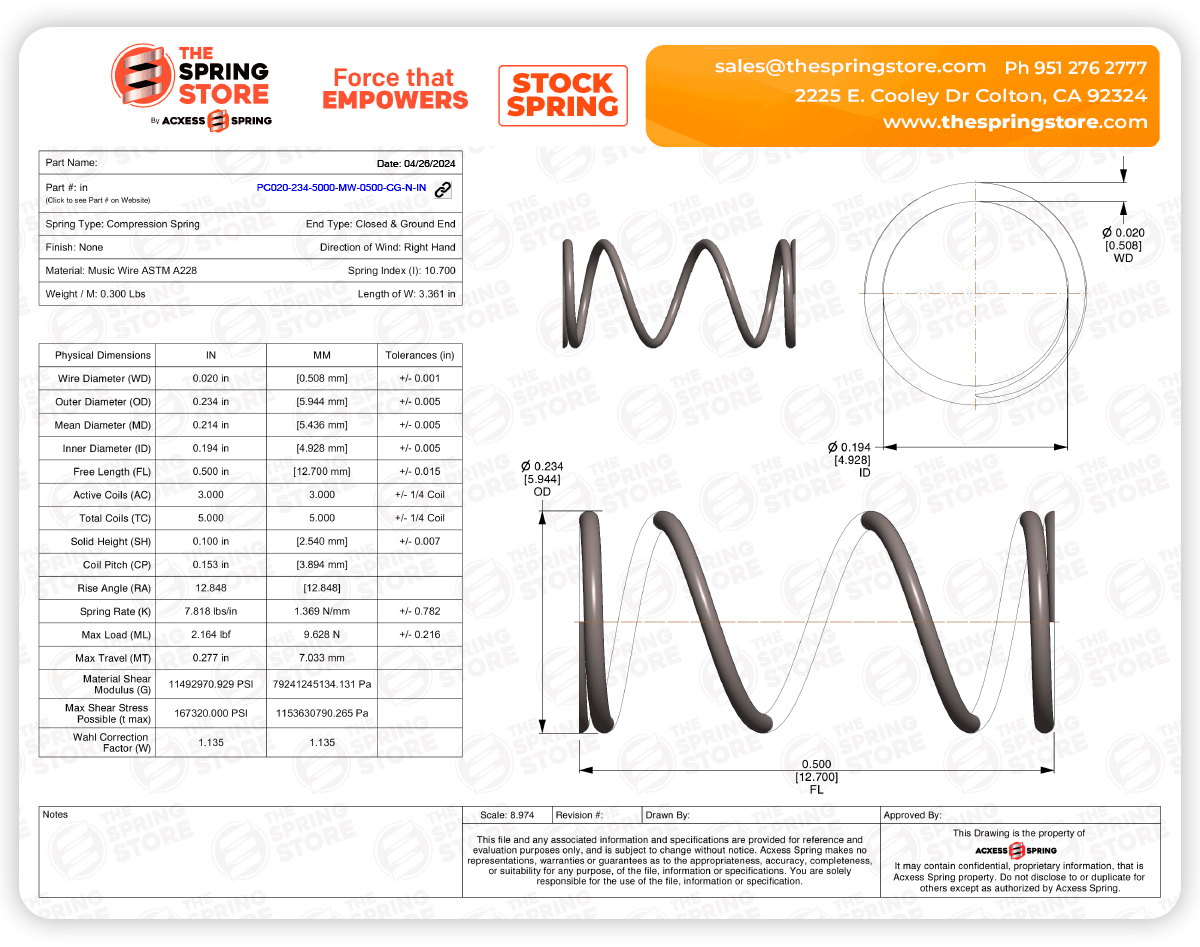

- Detailed Spring Specifications: For each spring that matches your criteria, the tool provides detailed specifications, including spring rate, maximum load, and maximum deflection. This detailed information is essential for making an informed decision, ensuring that the spring will perform as expected under the specified operational conditions.

- CAD Downloads: Spring Finder 5.0 offers downloadable 3D Spring CAD models in multiple formats for each listed spring. This feature is incredibly valuable for designers and engineers, as it integrates seamlessly into digital prototypes, allowing for precise fitting and simulation tests before making a purchase decision.

Step 1: Access the Tool

- Navigate to the Website: Start by visiting the The Spring Store website. Look for the ''Spring Finder 5.0” icon and open the tool up.

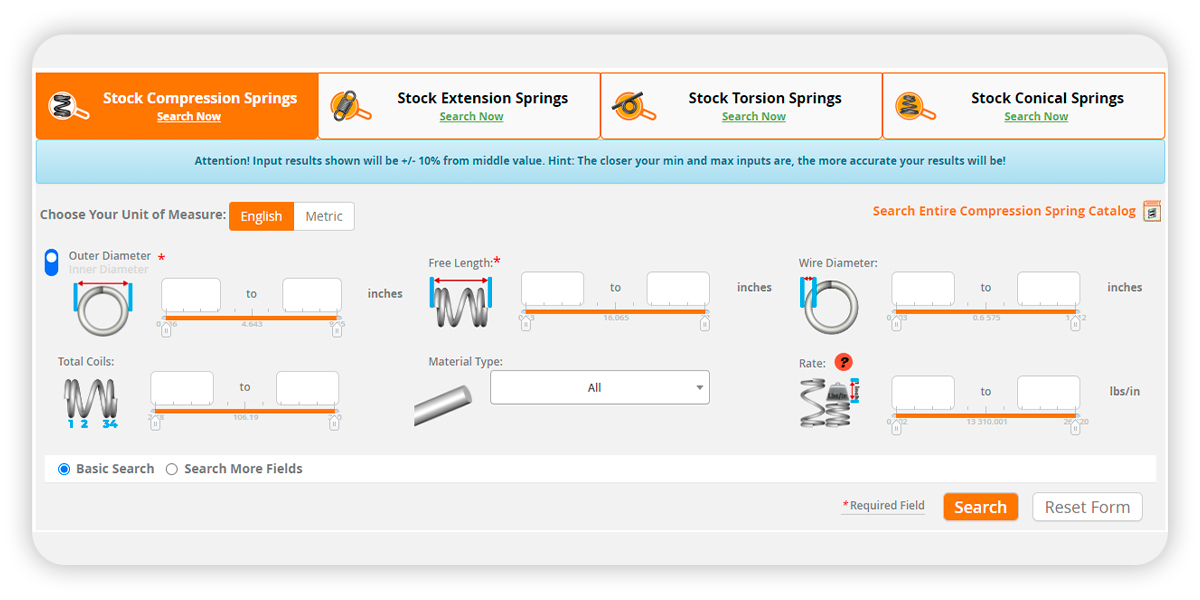

Step 2: Enter Your Specifications

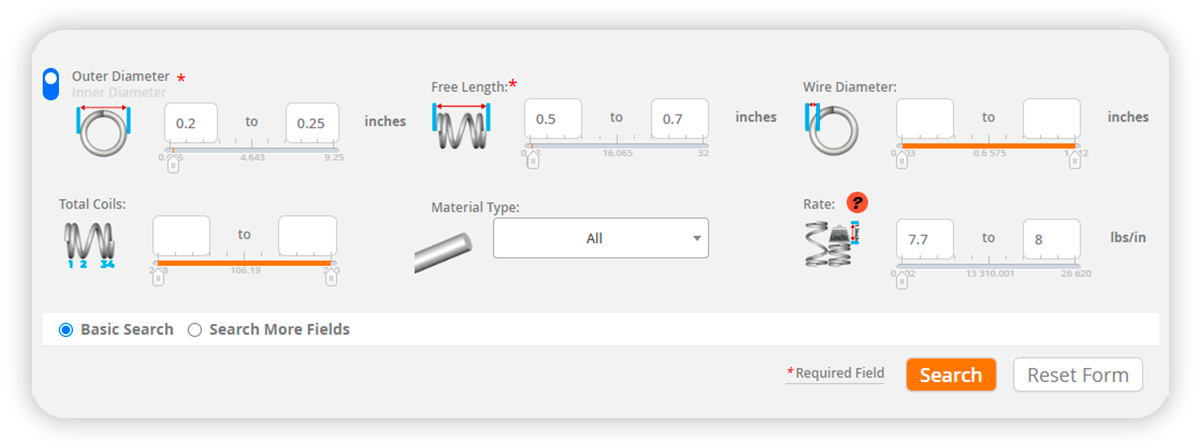

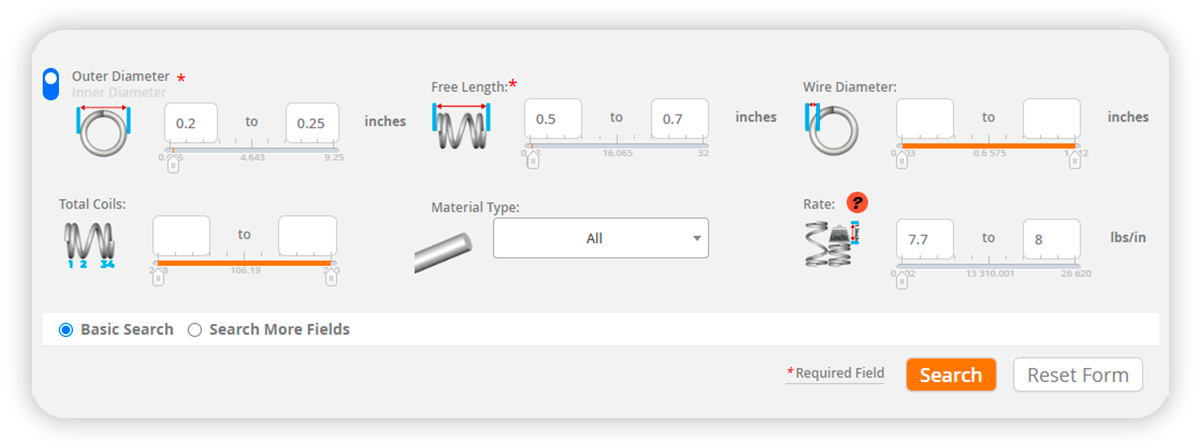

- Input Basic Dimensions: Begin by entering the essential dimensions of the compression spring you need. These include the outer diameter or inner diameter, free length, and wire diameter.

- Specify Performance Requirements: Input performance criteria such as max load or max deflection or travel. This will help in finding springs that meet your operational demands.

- Material and Design Preferences: Choose the material for the spring based on the environment in which it will operate, like stainless steel for corrosion resistance.

Step 3: Analyze the Results

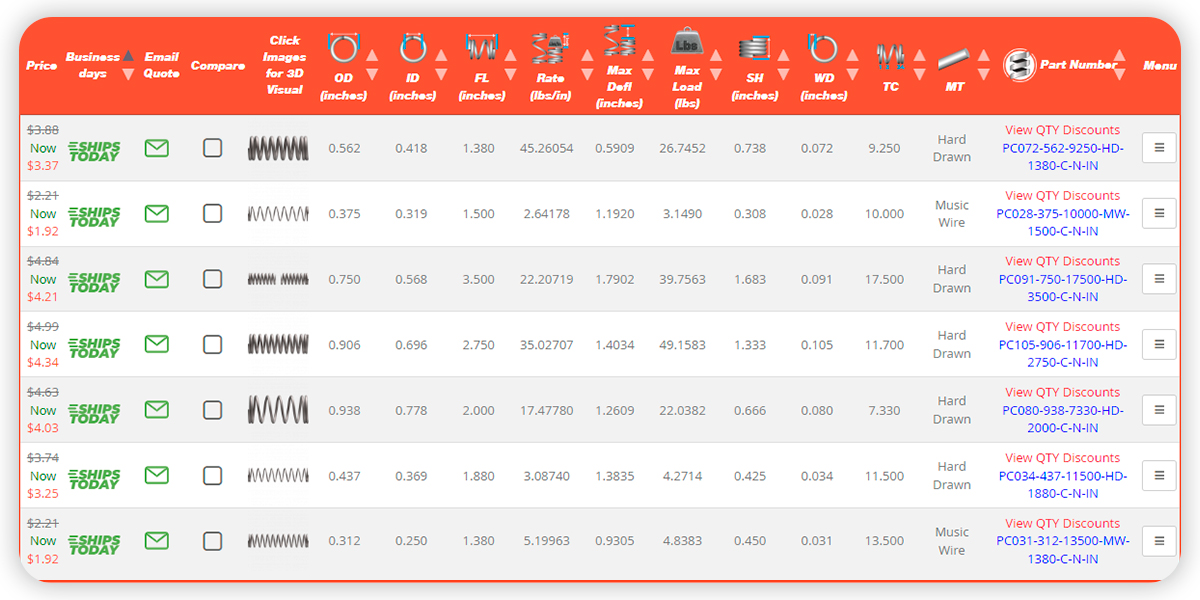

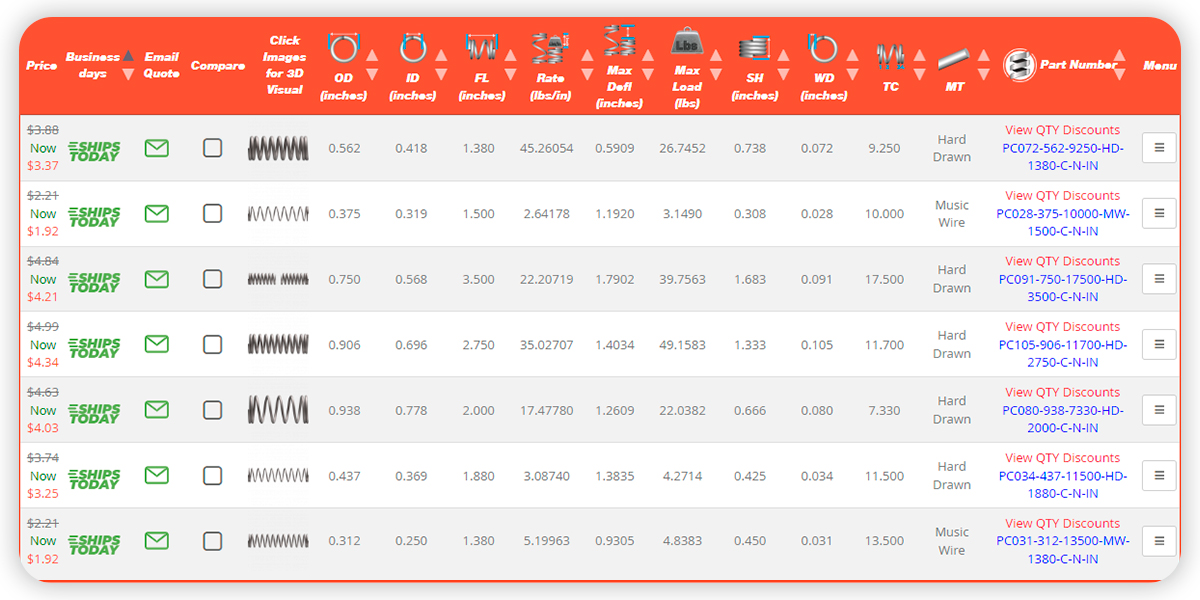

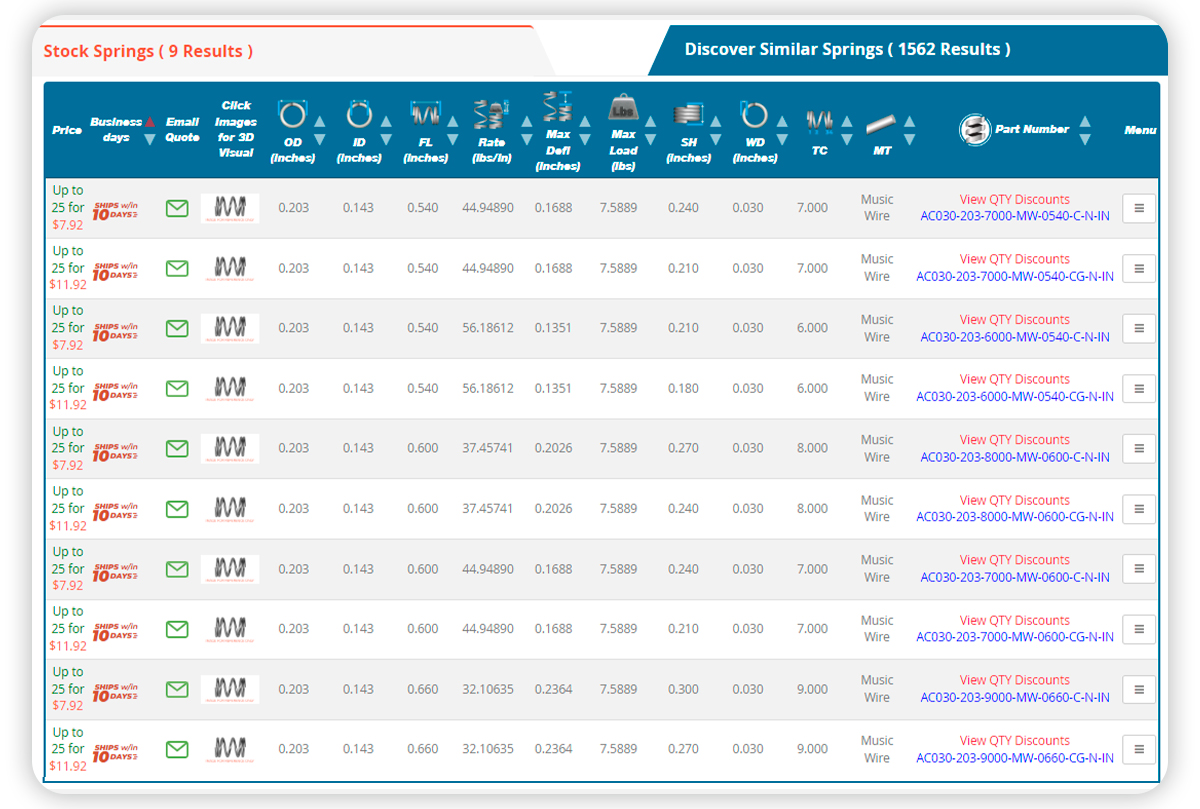

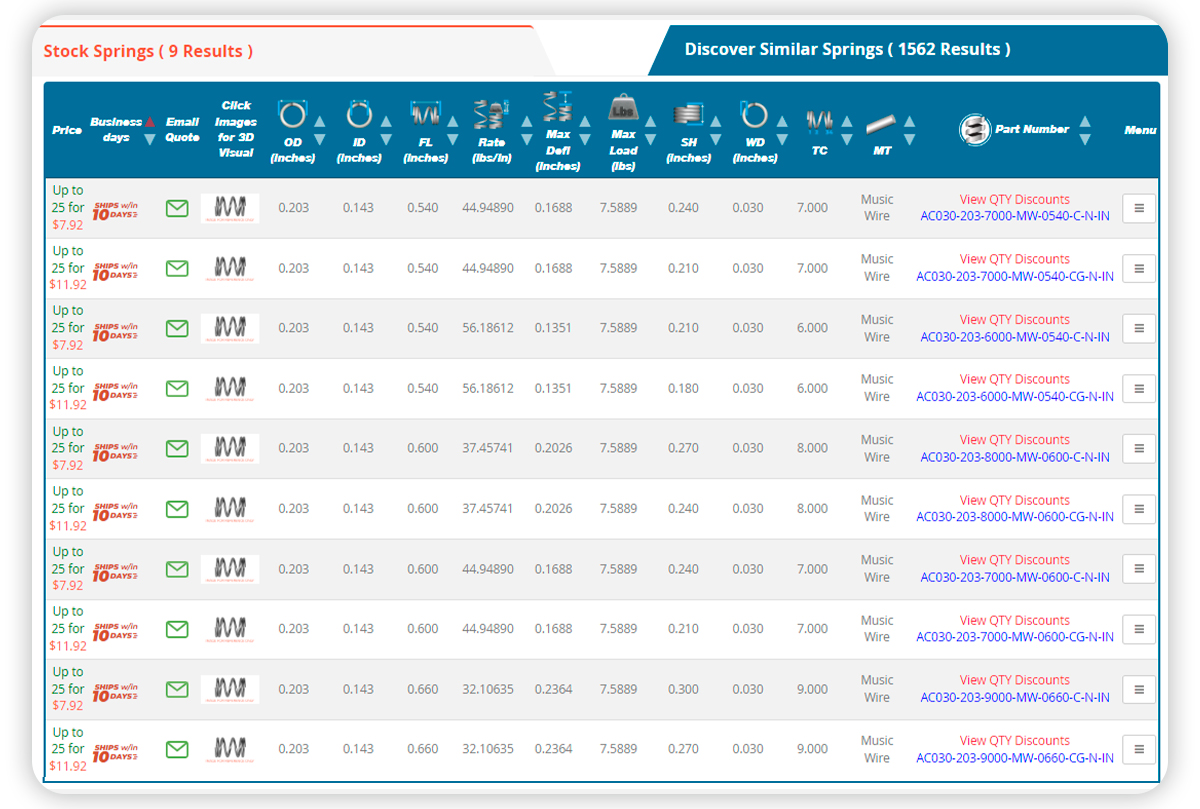

- Review Matching Springs: The spring finder 5.0 tool will display a stock spring orange tab and a discover similar springs blue tab with a long list of compression springs that match your criteria. Each compression spring listing will include all the comprehensive compression spring specifications such as outer diameter, free length, max load, max travel and price. The Spring Finder 5.0 algorithm generates (at the time of search) thousands of similar spring designs on the Blue Tab for you to choose from. Thousands of weaker and stronger spring options are available in the blue “Discover Similar Springs” tab. Spring Finder 5.0 gives you millions of compression spring possibilities where you will always find the right compression spring for your application.

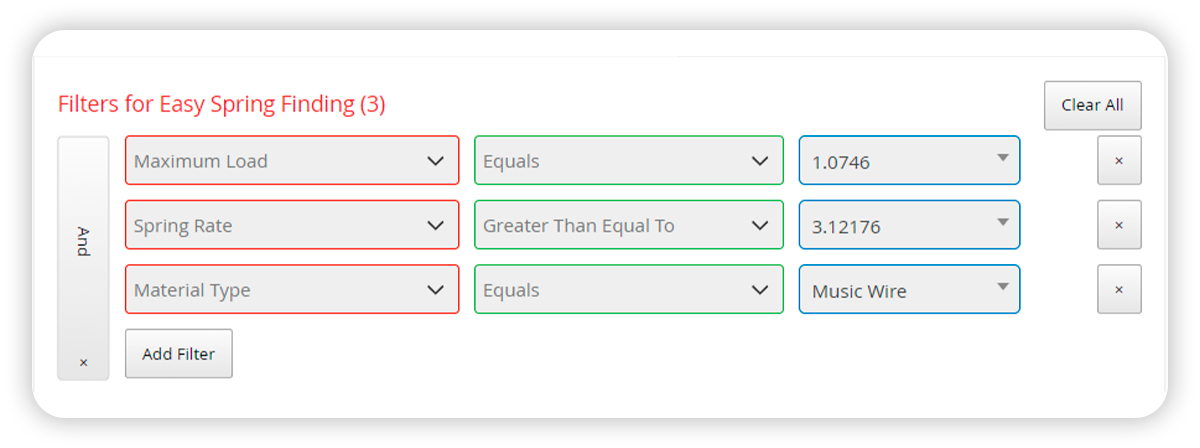

- Use Filters: Spring Finder 5.0 includes powerful filtering tools for easy spring finding to further refine your results. You can filter by any spring specification like max load, spring rate, material type, and even max deflection. This can be particularly helpful if you're faced with thousands of potential options and need to narrow down your spring choices to the most viable candidates.

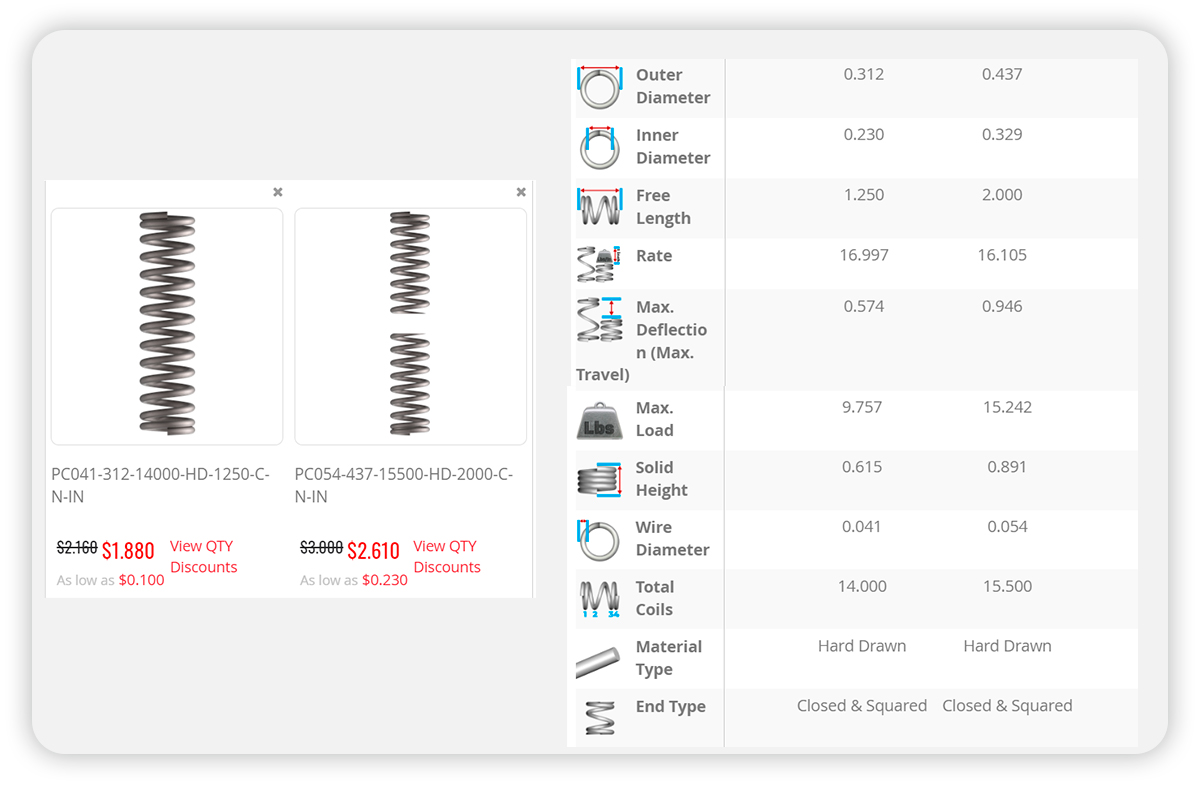

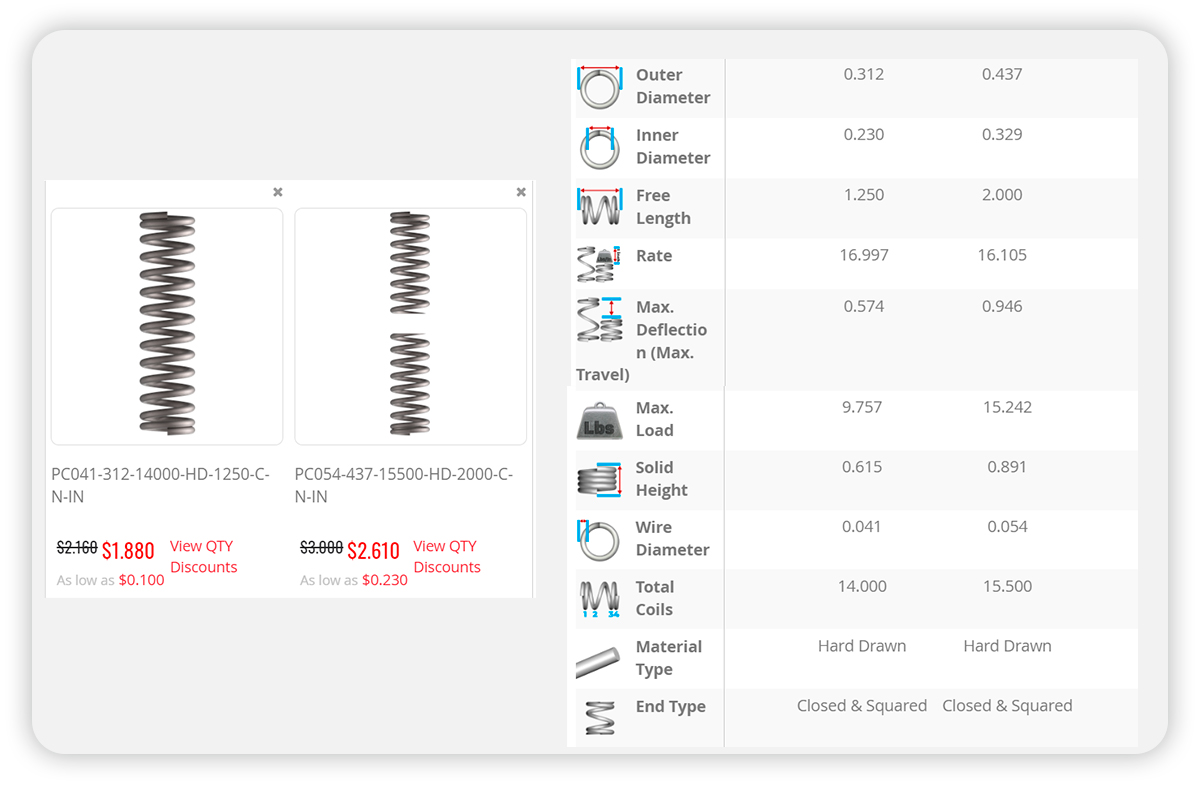

- Compare Options: Use the comparison feature to select multiple springs and directly compare their specifications side-by-side. This is particularly useful for closely evaluating slight variations between different springs.

- Once you have your search results, Spring Finder 5.0 offers two advantageous paths depending on your immediate needs and specific requirements. For quick solutions, you can utilize the Orange Tab 'Stock Spring' List. This feature displays springs that are readily available and can be shipped today if the order is placed before noon. This option is perfect for urgent requirements where time is of the essence. Alternatively, if the available stock springs do not meet your exact specifications, you can opt for the Blue Tab 'Discover Similar Springs' feature. This option allows you to explore thousands of custom compression springs that are designed at the time you input your compression spring dimensions to meet your precise requirements. The Spring finder 5.0 AI algorithm designs at that moment thousands of stronger, weaker and similar compression spring options for you to choose. Literally thousands of compression spring designs with only a few inputs. This route is ideal for applications that require specific modifications or when a perfect fit and performance are critical. Both options ensure that you can find the best compression spring solution efficiently, whether it's from readily available stock or a customized design to meet specialized needs. Stop searching for compression springs and start finding your compression springs with Spring Finder 5.0 with AI.

Step 4: Download CAD Models

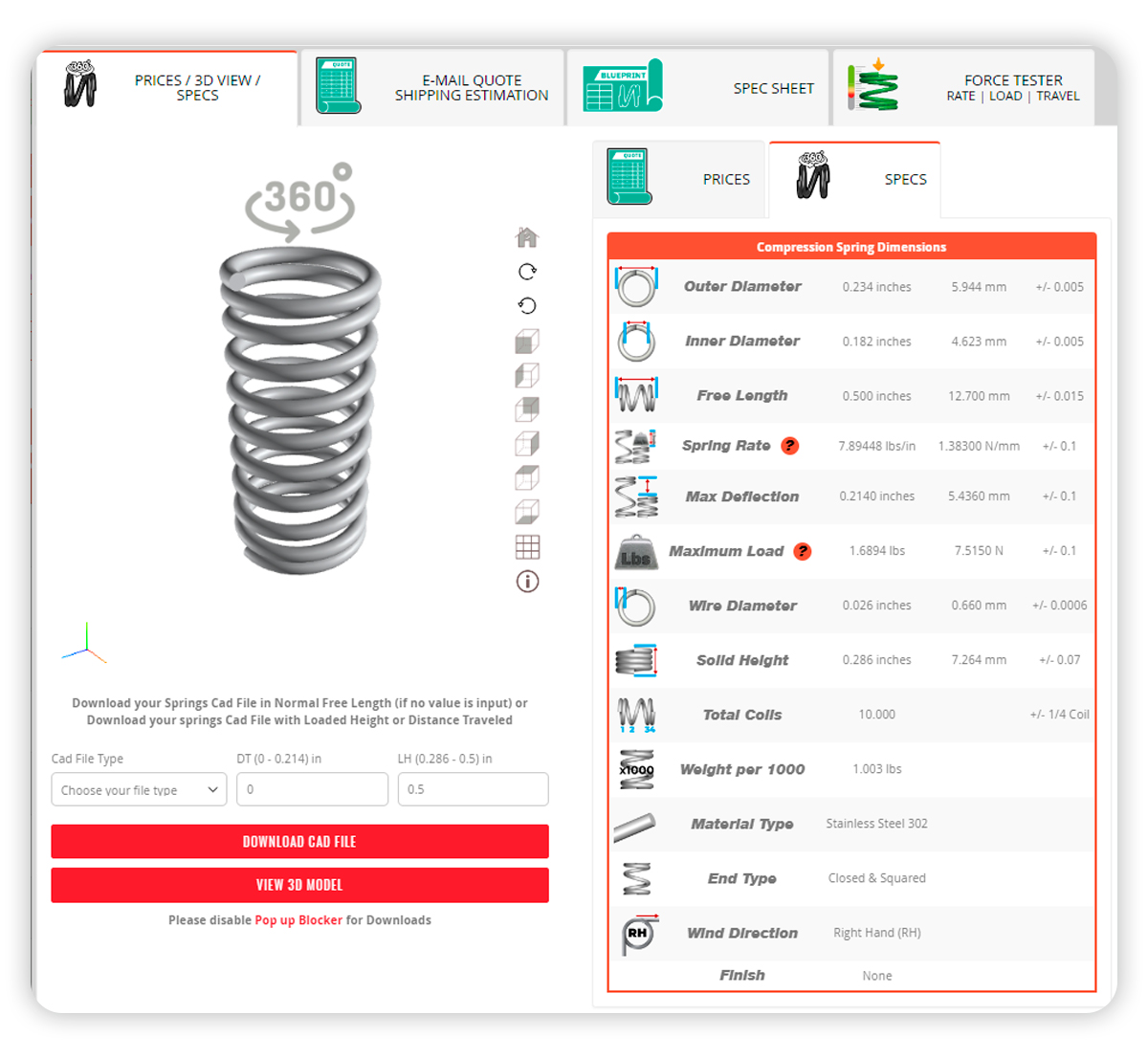

- Select a Spring: Once you have chosen a spring that fits your requirements, click on its part number to view more detailed information.

- Download CAD Files: From the detailed view, download the 3D CAD model of the spring in various formats compatible with your design software. This integration allows you to test the spring in your digital prototype immediately.

Step 5: Test with the Online Spring Force tester (OSFT)

- Introduction to OSFT: The OSFT is a feature provided by Acxess Spring designed to help you conduct comprehensive visual tests on your selected springs. This framework supports a variety of tests including rate, travel, and load testing.

- Run Simulations: Input the operational parameters under which the spring will function within your product. This can include different loads and loaded heights.

- Analyze Test Results: Review the data collected during simulations to ensure the spring can handle the specified load and loaded height demands.

Step 6: Request a Quote

- Request An Instant Quote: Open the Email Quotation tab and email yourself an instant quote of the spring you're interested in. Your instant quote will be sent to your email at that moment along with the Blueprint / Spec-Sheet of your compression spring.

- Utilize User Support: If you encounter any issues or have questions about a specific spring, don't hesitate to contact Acxess Spring’s customer support for assistance. 952- 276- 2777

- Check for Updates: Regularly check for updates to the Spring Finder tool, as new features and improvements are continuously being added to enhance user experience and accuracy.

By following these steps, users can fully leverage the capabilities of the Spring Finder 5.0 to find the optimal compression spring for their needs efficiently and effectively. This guide aims to ensure a smooth user experience, from initial search to final selection and purchase.

Outer Diameter (OD)

- Definition: The outer diameter (OD) is the overall external measurement across the spring, spanning the outside of the wire on two opposite sides.

- Importance: Selecting a spring with the correct outer diameter is crucial because it ensures the spring will fit within the mechanical bounds of your application without interfering with adjacent parts. An incorrect OD can lead to operational failures, as the spring may rub against other components or not fit into its designated space.

- How to Measure: To measure the outer diameter, use digital calipers for accuracy. Place the caliper jaws around the outside of the spring, ensuring they touch the widest part without compressing the spring. If the spring is installed, ensure there is no load on it while measuring.

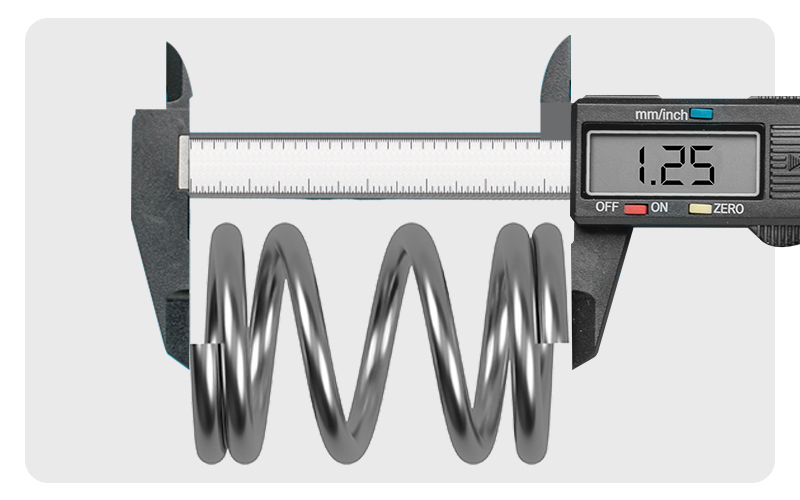

Free Length (FL)

- Definition: The free length is the total height of the spring when it is fully extended and not under any load or compression.

- Importance: This dimension is essential for ensuring the spring has enough room to compress and expand during operation, which is vital for achieving the desired mechanical performance and lifecycle. An incorrect free length could either prevent the spring from fitting into its assembly or fail to meet operational deflection requirements.

- How to Measure: Place the spring upright on a level surface and use a ruler or caliper to measure straight from the base to the top end. Ensure the spring is not compressed or stretched and that the measuring tool is perpendicular to the surface for an accurate reading.

Wire Diameter (WD)

- Definition: This is the thickness of the individual wire used to coil the spring.

- Importance: The wire diameter significantly impacts the spring's strength and flexibility. A thicker wire will typically handle more load but offers less flexibility, which can affect the spring's ability to absorb shock and its overall durability. Choosing the right wire diameter ensures the spring can endure the operational stresses without premature failure.

- How to Measure: Using calipers, measure the wire’s thickness by placing the caliper on the wire's cross-section. Ensure the caliper does not compress the wire. It's advisable to measure at several points along the spring to account for any potential variations in the wire thickness.

Material Type

- Importance: The choice of material affects the spring’s performance under various environmental conditions, such as temperature extremes and corrosive environments, and its mechanical properties like tensile strength and durability.

- Selection Guide: When selecting a material, consider the environment in which the spring will operate. For example, stainless steel is ideal for corrosive environments, while music wire is suitable for high-stress applications. Be sure to consider both environmental and mechanical requirements to ensure optimal performance and longevity.

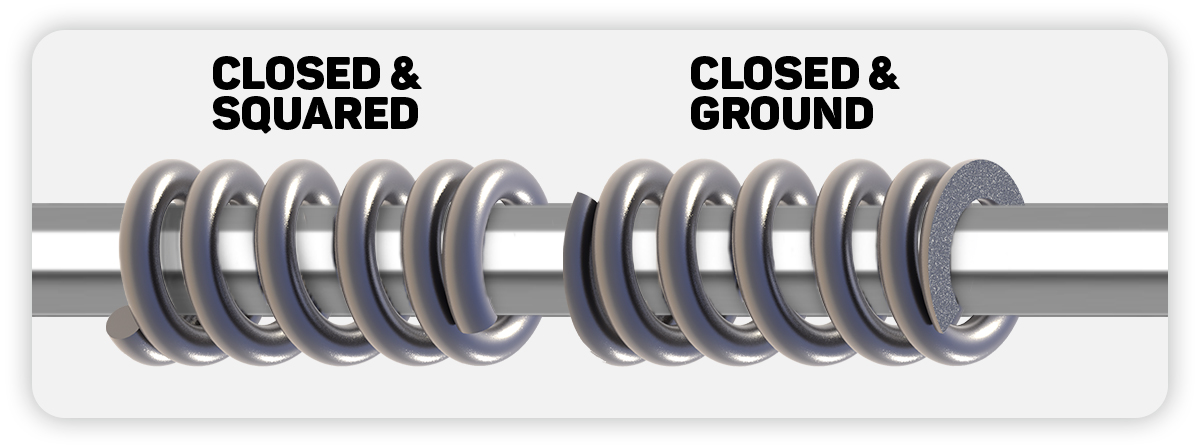

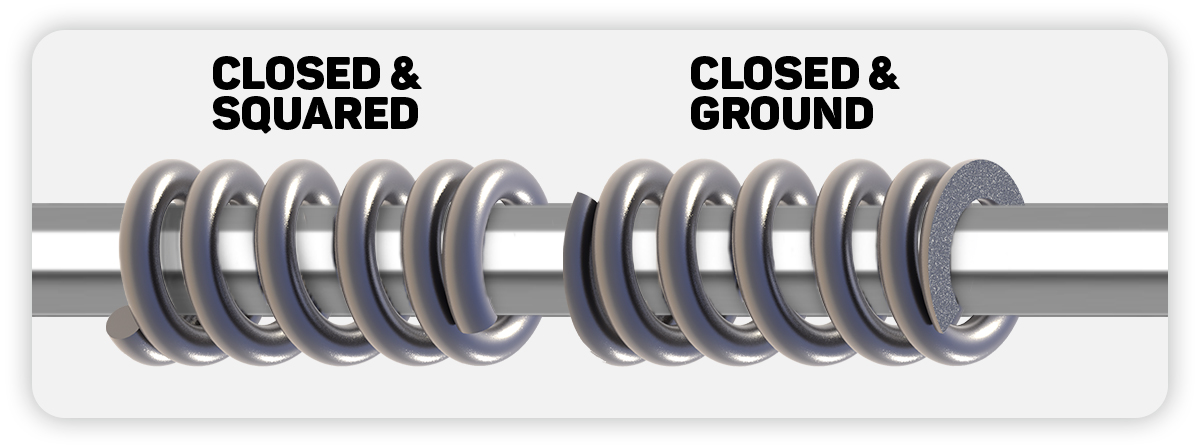

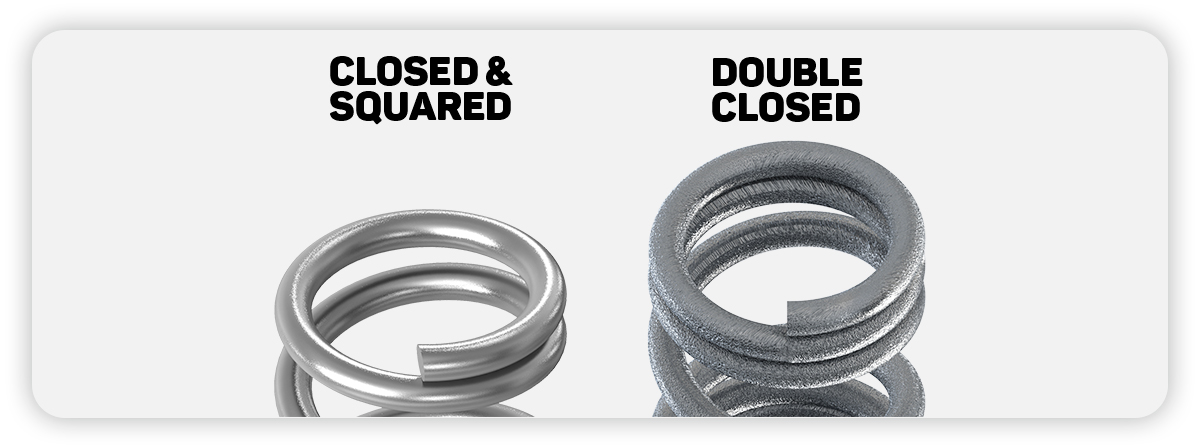

Compression Spring End Types

- Definition: This refers to the configuration of the spring’s ends, which affects how the spring interacts with its load and mounting surface.

- Importance: The end type can significantly affect the spring's stability and how uniformly the load is distributed across the coil. Proper selection can prevent uneven loading, which might lead to premature failure.

- Options: Choose from several end types, such as open, closed, closed and ground, or double ends, based on the application requirements. Closed and ground ends are generally recommended for maximum stability and uniform loading, but may increase manufacturing costs.

Using the Spring Finder 5.0 offers several benefits:

- Efficiency: Converts searching for compression springs into Finding the right compression spring fast. Dramatically reducing the time typically required to find the right compression spring.

- Precision: Ensures that the selected springs meet specified criteria exactly, thanks to the biggest compression spring database of over 70 Trillion Spring Configurations.

- Convenience: Built in Custom Spring 3D CAD Builder. The ability to download 3D Compression Spring Custom and Stock 3D CAD models and request instant quotes directly through the tool simplifies the subsequent steps in the procurement process.

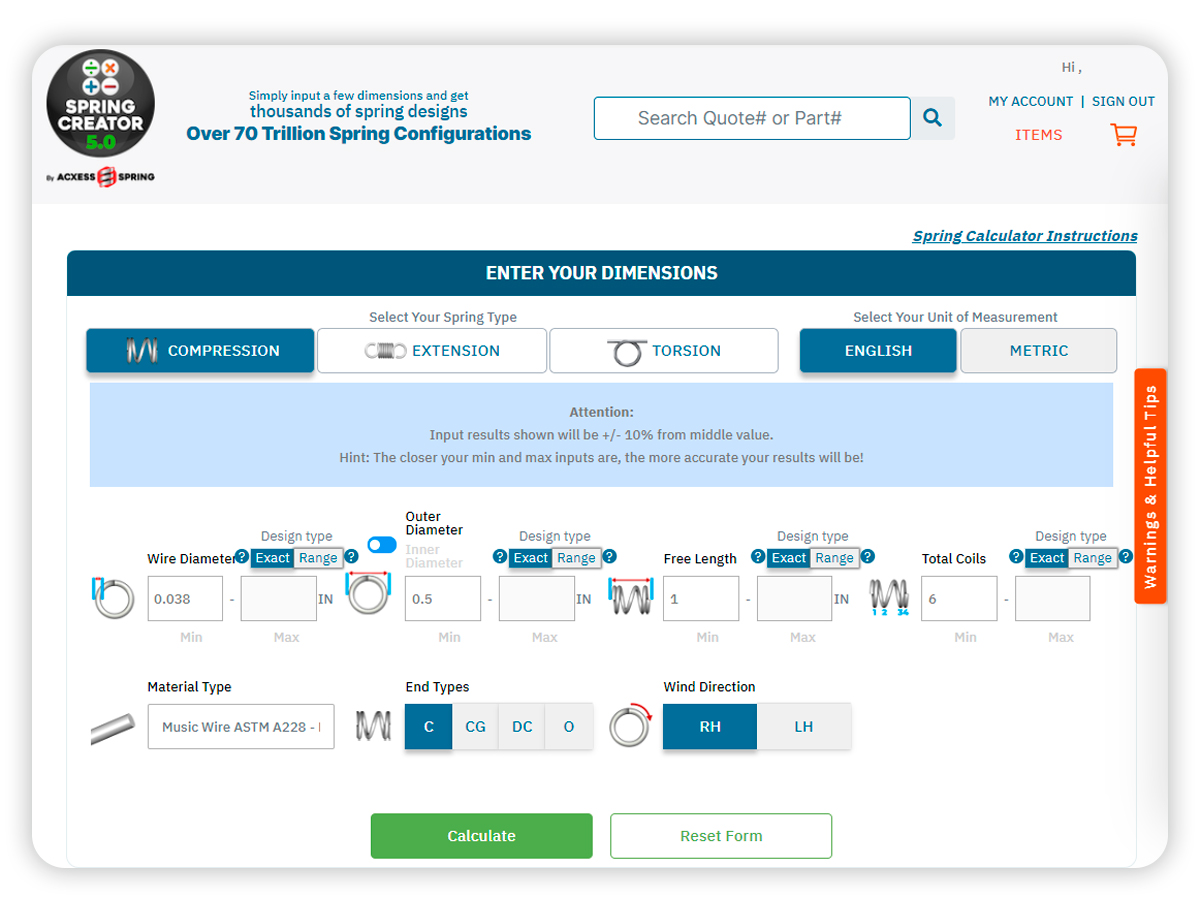

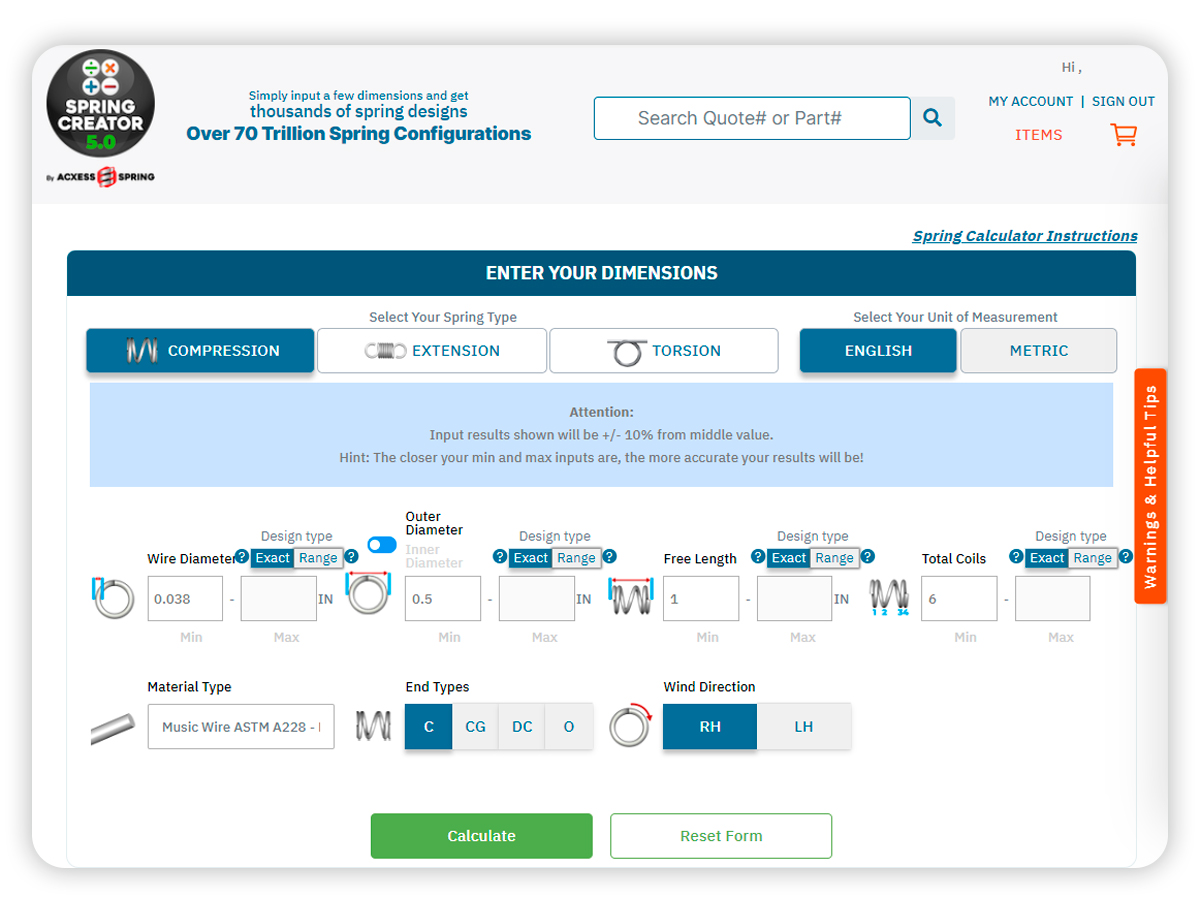

When off-the-shelf springs cannot meet unique specifications required for specialized applications, Spring Creator 5.0 offers a robust solution. This advanced spring design tool is designed for creating custom springs from scratch, allowing users to input precise specifications and see real-time modifications. Below, we detail the key features and benefits of Spring Creator 5.0.

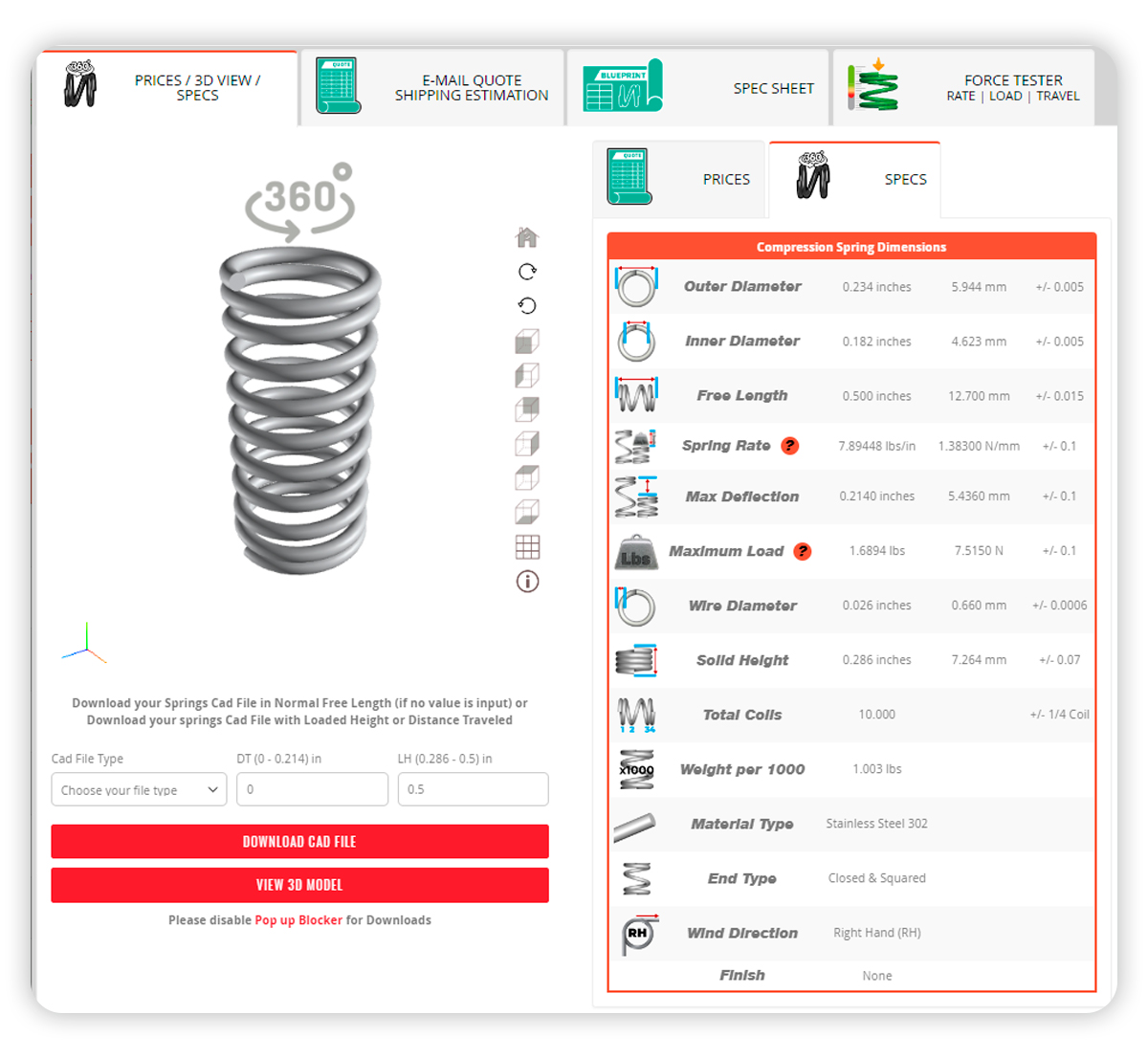

- Customizable Design Parameters: Spring Creator 5.0 allows users to input a wide range of design parameters such as wire diameter, outer diameter, free length, total coils, and material type. The tool adjusts its calculations in real-time as each parameter is modified, providing immediate feedback on how changes affect the spring's physical characteristics and performance metrics.

- Advanced Material Selection: Users can select from a comprehensive list of materials each with distinct properties suitable for different operational environments. This selection includes options like stainless steel for corrosion resistance, music wire for high tensile strength, and chrome silicon for superior fatigue life, enabling the creation of springs optimized for specific applications.

- Real-Time Performance Metrics: As you design your spring, Spring Creator 5.0 provides instant updates on crucial performance metrics such as spring rate (stiffness), load capacity, and safe maximum deflection. This feature ensures that the custom spring will meet the operational demands of its intended application before finalizing the design.

- Integrated Visual Stress Analysis: The tool includes an integrated spring stress analysis feature that's called the “Online Spring Force Tester” that calculates the working stresses within the spring based on the entered design parameters. This visual animation analysis helps in identifying potential failure points and ensures that the spring design is robust enough for long-term use.

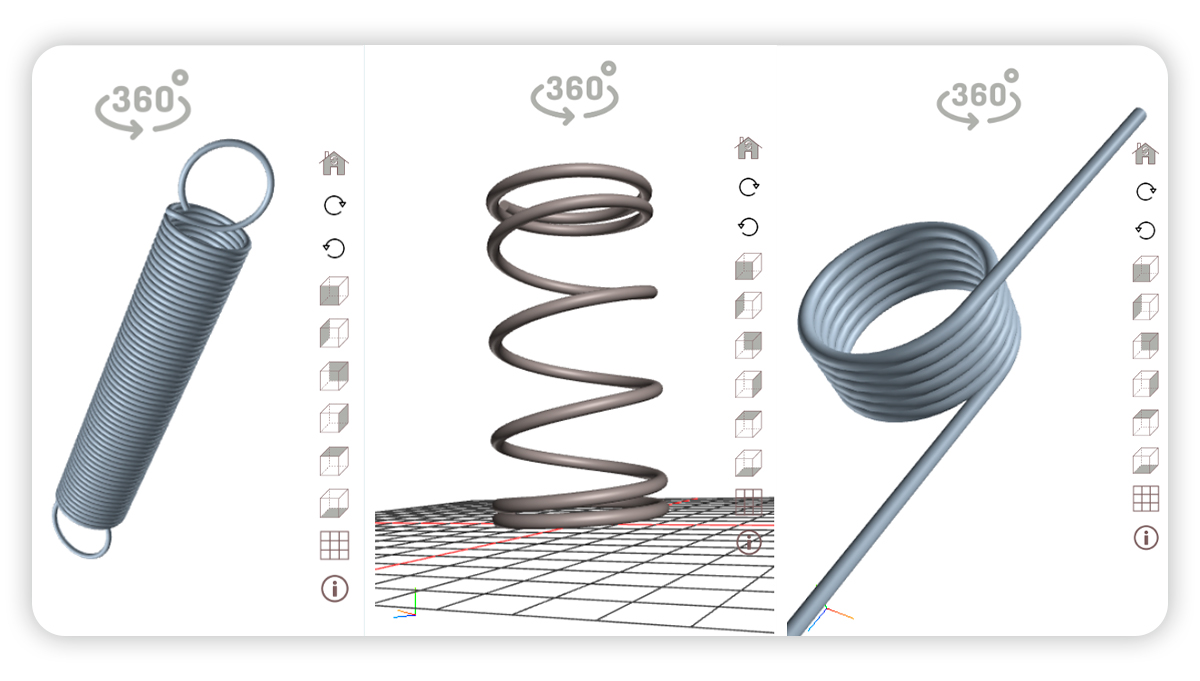

- 3D Spring Modeling and Visualization: Spring Creator 5.0 offers a 3D model view of the designed spring, which can be rotated and examined from different angles. This visualization aids in verifying the scale, size and type of spring and ensuring that the compression spring will fit precisely in the intended assembly.

- Precision Engineering: By allowing for precise input of specifications and immediate feedback on changes, Spring Creator 5.0 enables engineers and designers to fine-tune their spring designs for optimal performance, reducing the need for multiple prototypes and speeding up the development process.

- Cost Efficiency: The tool's ability to predict performance and conduct stress analysis before manufacturing helps in reducing costly trial-and-error testing. This ensures that the custom springs are right the first time, lowering the overall production costs.

- Enhanced Compatibility and Integration: The downloadable 3D Custom Spring CAD files and detailed blueprint performance metrics make it easier to integrate the custom spring into broader design projects. Engineers can directly import these files into their design software, streamlining the development workflow.

- Scalability: Spring Creator 5.0 is scalable to any project size, from a single custom spring for a specific device to large-scale production for commercial applications, providing the same level of precision and reliability.

Spring Creator 5.0 by Acxess Spring revolutionizes the process of designing, calculating and manufacturing custom springs by providing powerful tools that enhance precision, efficiency, and integration. It enables users to create custom springs that are perfectly tailored to their specific needs, ensuring both performance and durability in their final applications. Whether you are an engineer looking to design a highly specialized component or a manufacturer needing to produce springs at scale, Spring Creator 5.0 offers the features and benefits necessary to succeed.

Spring Finder 5.0 by Acxess Spring represents a significant advancement in the task of finding the right compression spring. Its comprehensive search/find capabilities and user-friendly interface make it an indispensable tool for anyone looking to enhance the efficiency and accuracy of their compression spring selection process. Whether you’re designing a new product or seeking a replacement spring, Spring Finder 5.0 can help you find the perfect match quickly and reliably.