What is a Compression Spring?

Table of Contents:

- What is a Compression Spring?

- Understanding Compression Springs

- The Anatomy of Compression Springs

- What are Compression Spring End Types

- Compression Spring Material Selection

- Compression Spring Plating Options

- Measuring Your Compression Spring Instructions

- How to Calculate Spring Compression

- Calculating the Compression Spring Rate k

- How Do You Calculate the Load on a Spring?

- How Do You Calculate Compression Spring Loaded Height?

- What's the Difference Between Compression Spring Load and Compression Spring Constant?

- Elevating Engineering Accuracy with Spring Creator 5.0

- Seamless Selection Process

- Bring Your Innovations to Life

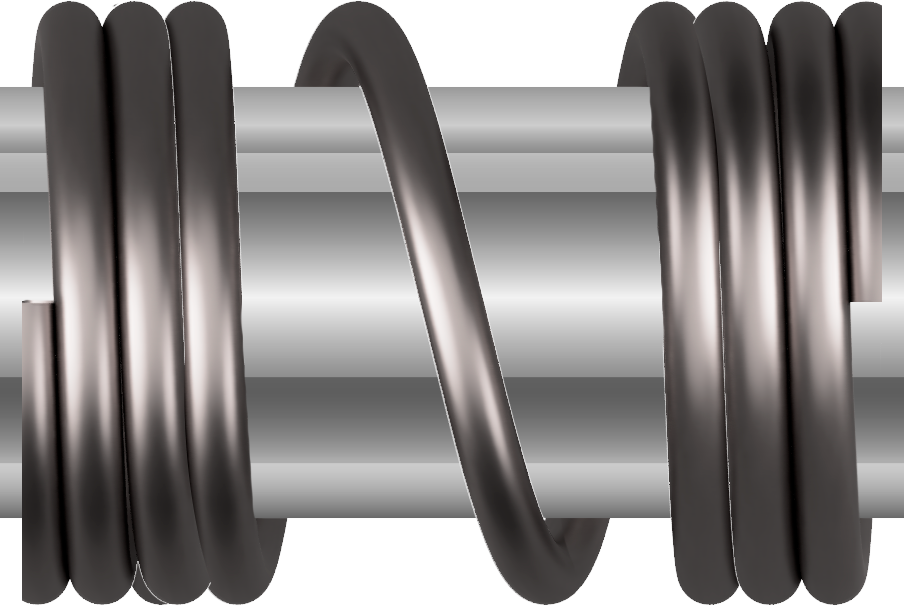

Definition: Helical coils wound one on top of the other with pitch in between to conserve or eject energy once a load is applied to the spring, therefore making the spring compress to a loaded height. In stock and readily available compression springs that exert force when compressed to a set height. Stock compression springs offer resistance to compression and absorb shock. Stock compression springs come in Music Wire ASTM A228 (High Tensile Steel Spring Wire) and Stainless Steel ASTM A 313 (High Tensile Stainless Steel Spring Wire)

Compression springs are engineered to compress under a load, acting as a form of energy storage that releases when the load is removed. They're essential in applications where mechanical energy storage or shock absorption is required. The versatility of compression springs makes them suitable for a broad spectrum of applications, from simple pens to complex aerospace mechanisms. In this article we will cover the anatomy of a compression spring, how to calculate compression spring constant, end types, material options, plating choices, compression spring load and compression spring loaded height. We will provide and in depth easily understandable analysis of compression springs down to a micro level.

Discover all the specifications that are needed for compression springs.

- Wire Diameter: The outer measurement of the spring’s round wire diameter from one side to the other.

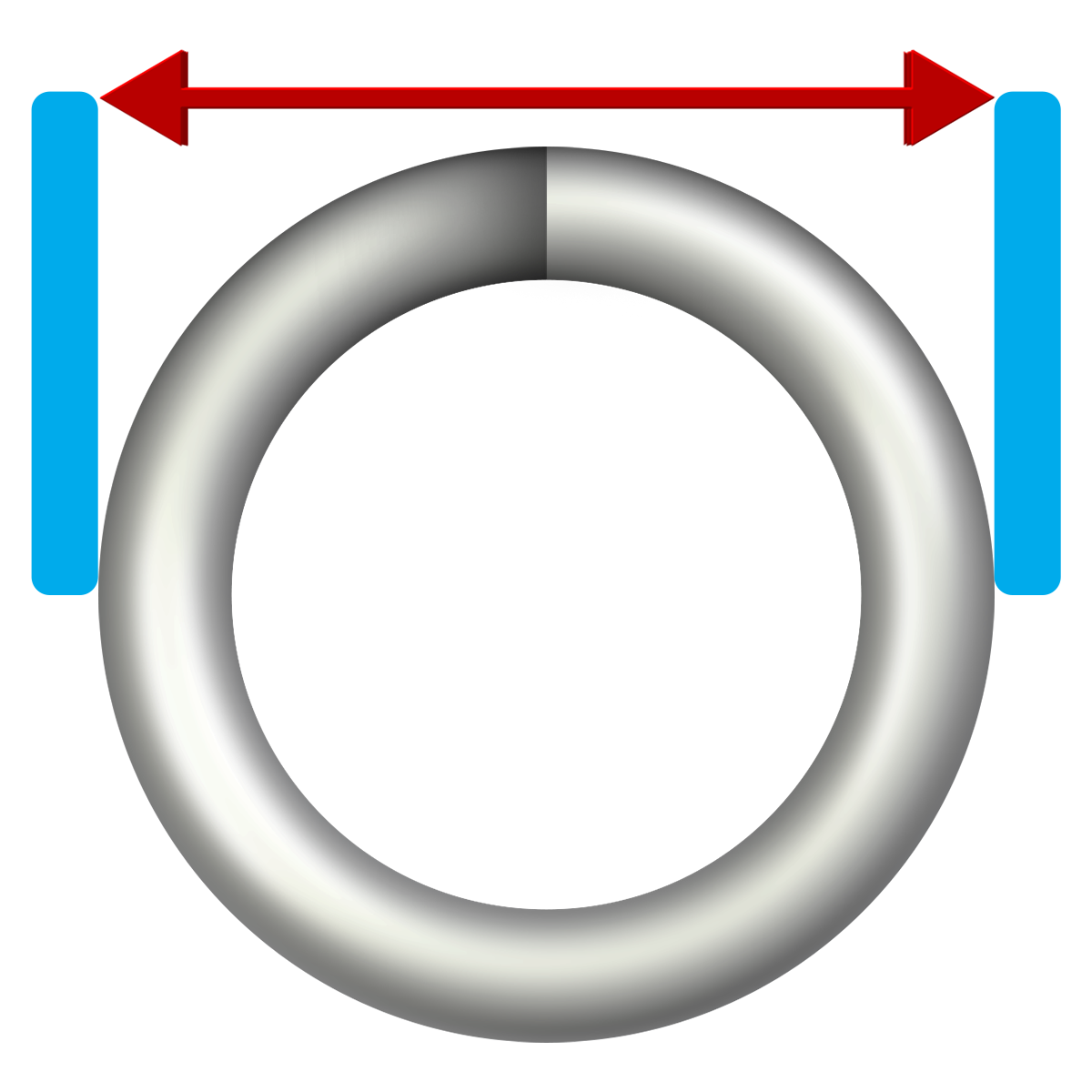

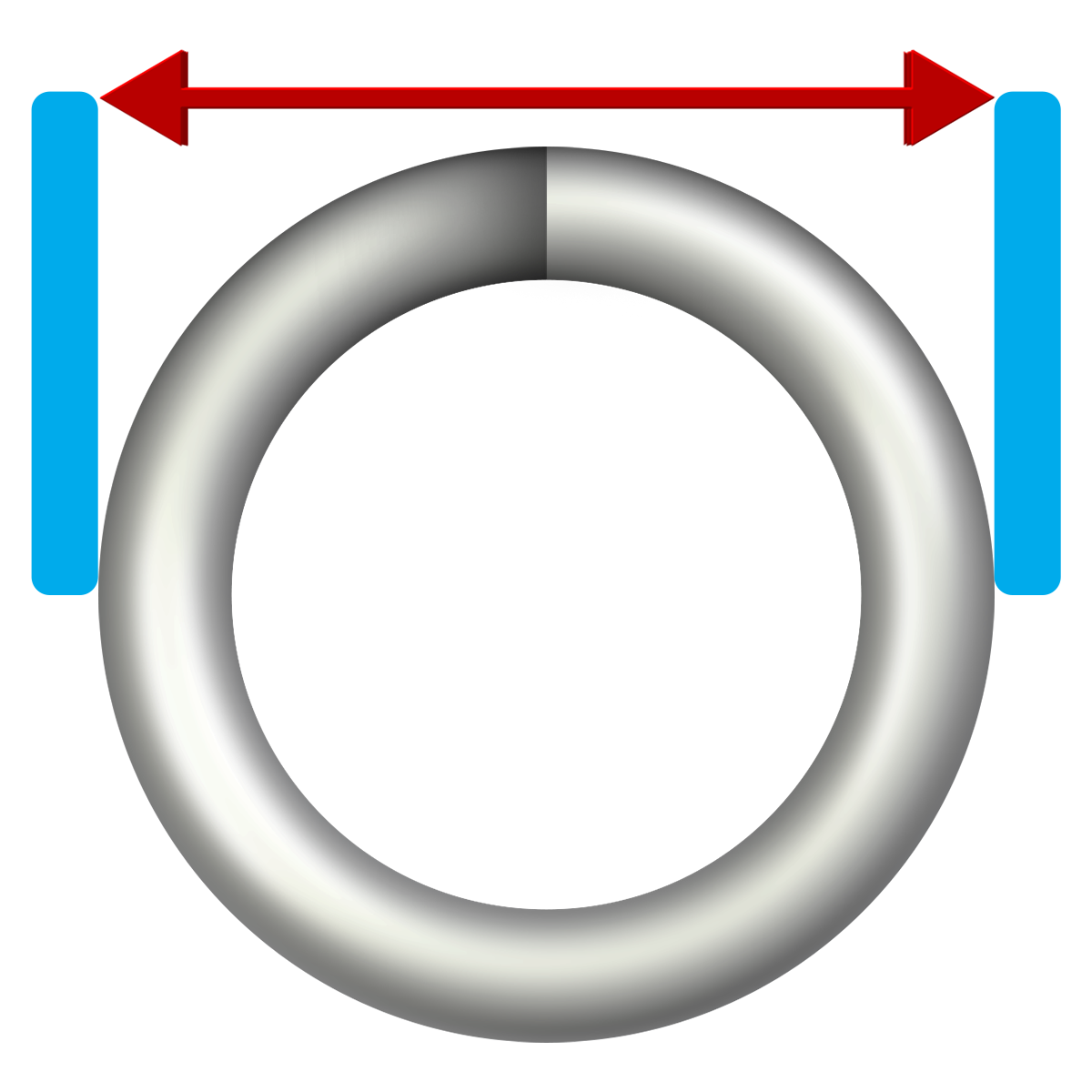

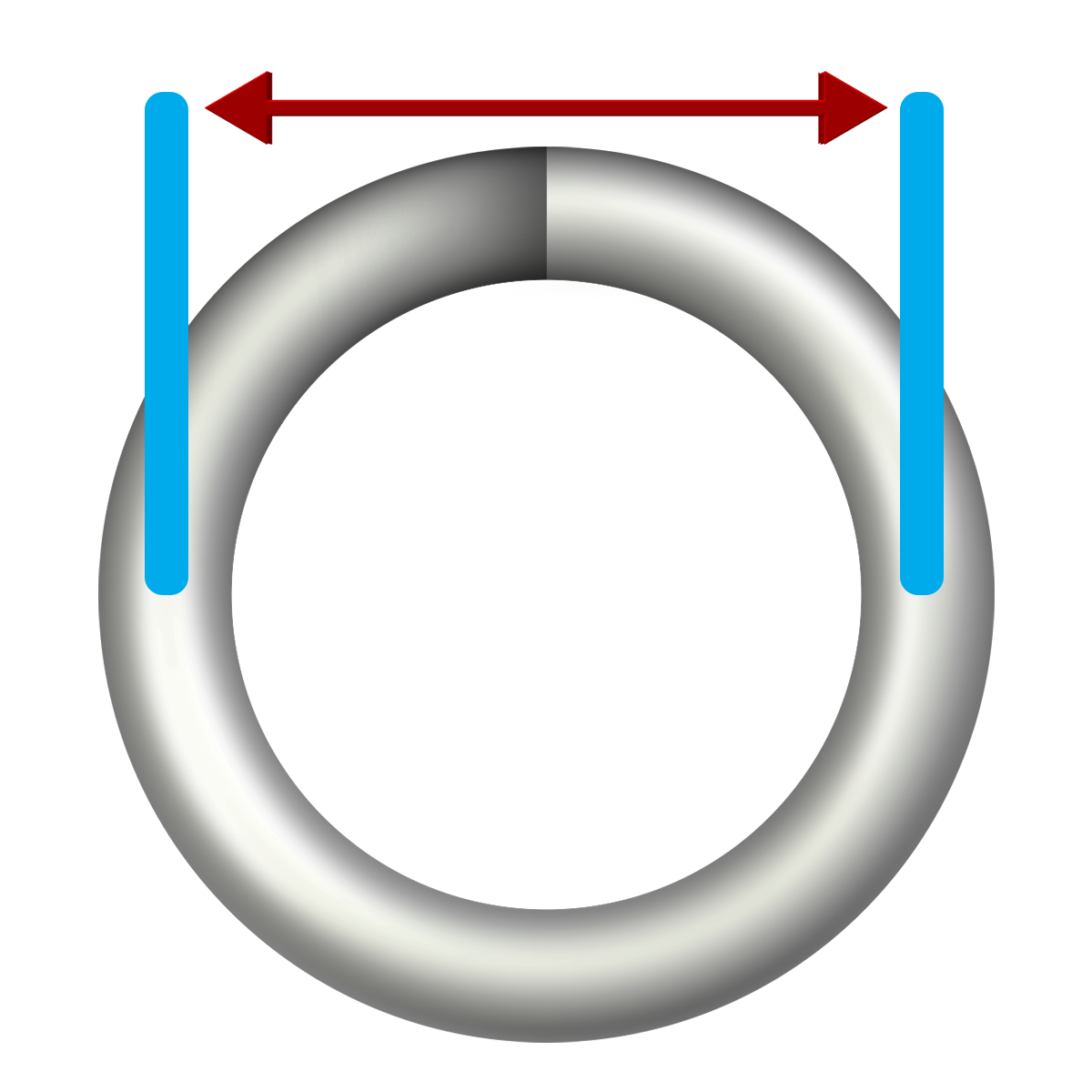

- Outer Diameter: The outer diameter of a compression spring from one side of the outer diameter to the opposite side of the outer diameter.

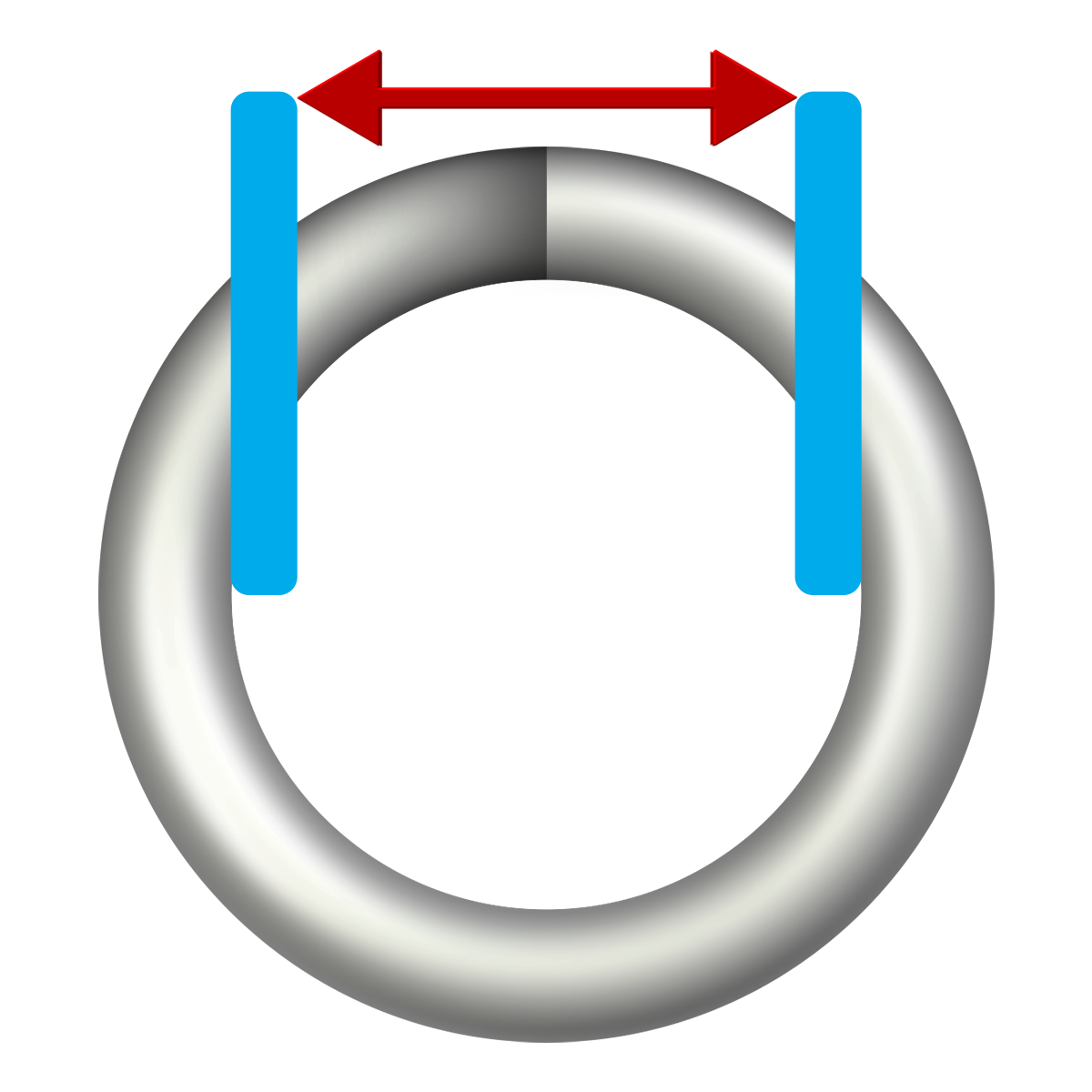

- Mean Coil Diameter: Compression spring specification that measures the diameter in between the spring’s outer and inner diameters. Meaning the measurement directly in between the compression spring’s outside diameter and inside diameter. Similar to your spring’s outer and inner diameters except, instead of measuring from the outside of the coil or the inside of the coil, you will measure from in between these spring dimensions; from the center of the coil’s wire to the center of the opposite side. It is the average of both outer and inner diameters.

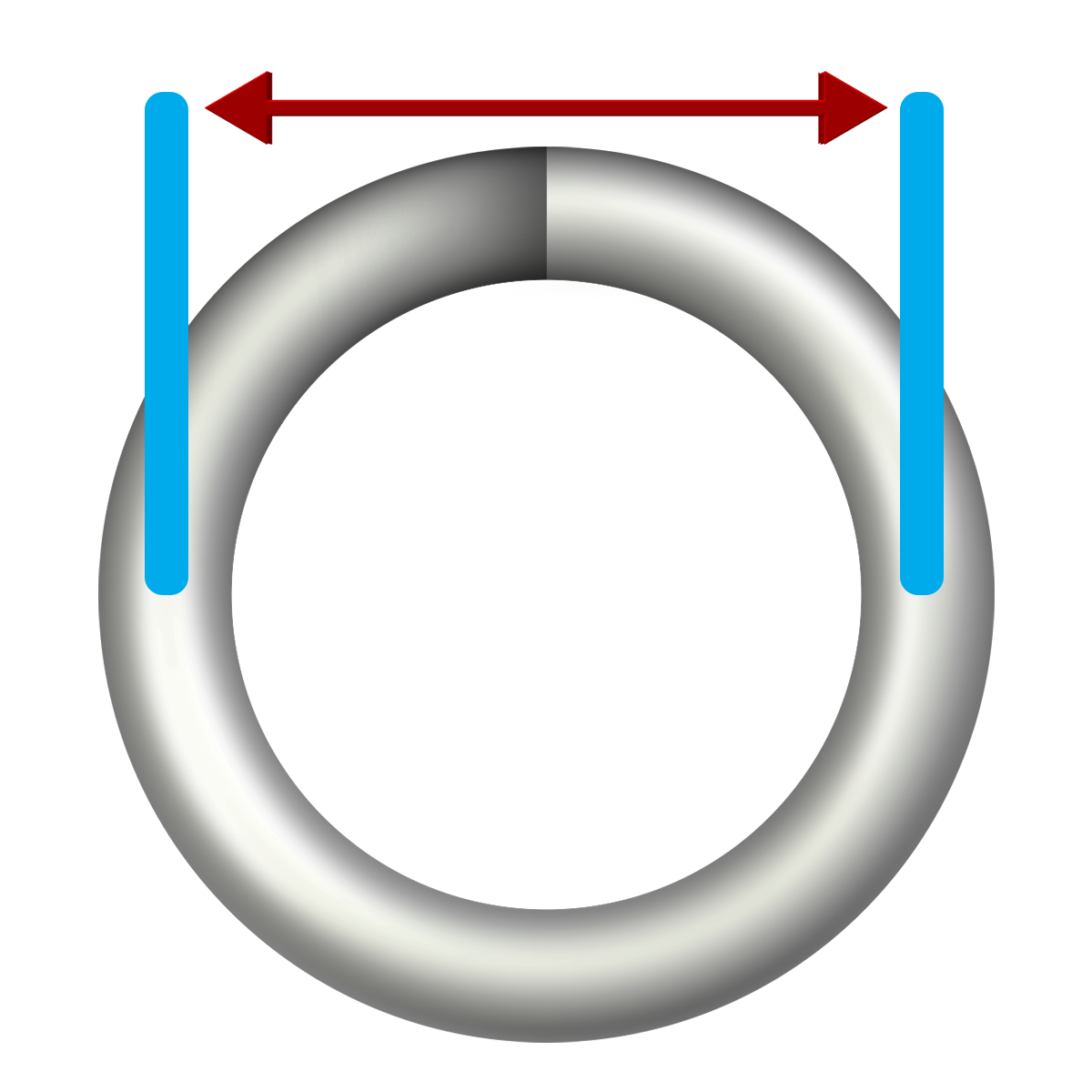

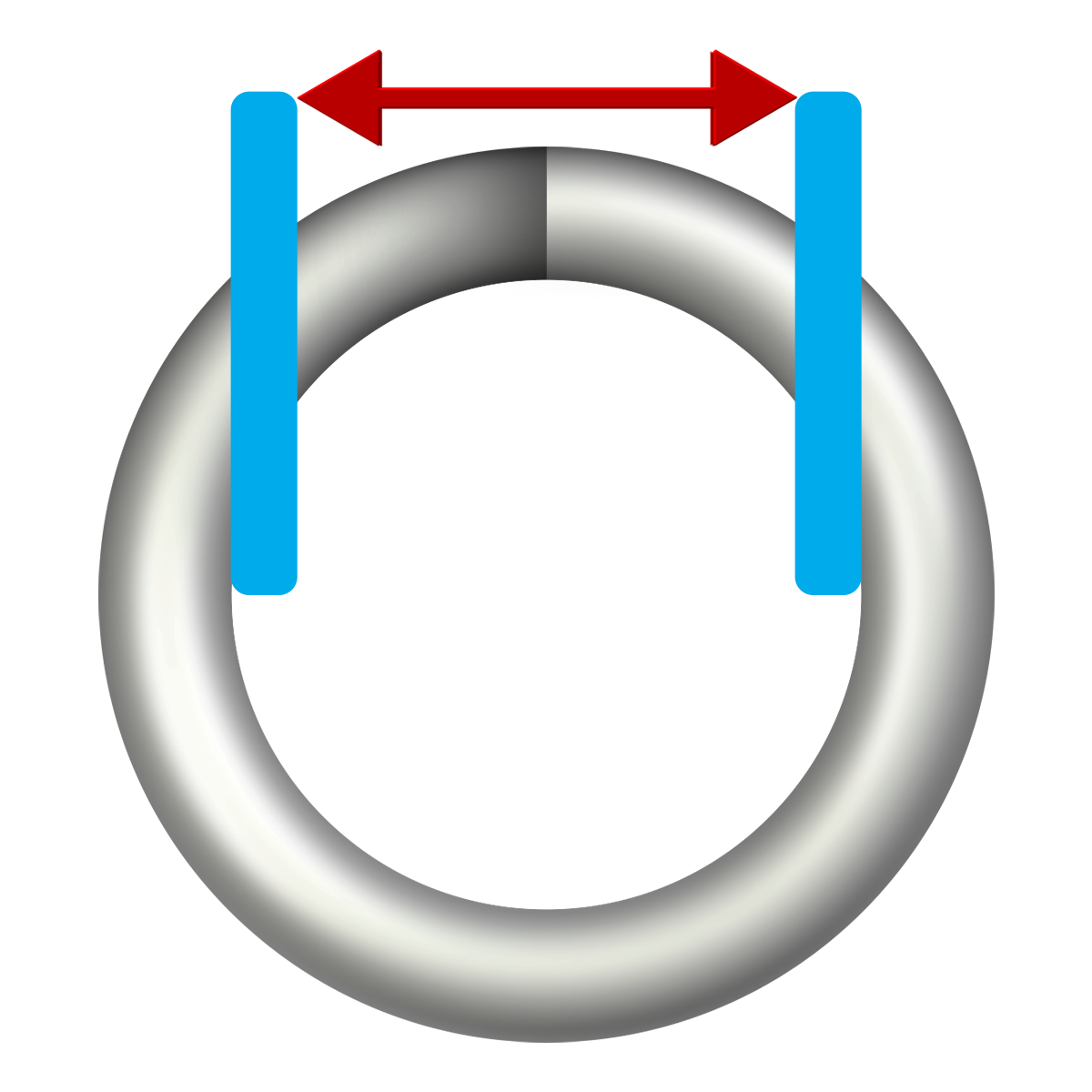

- Inner Diameter: The Inner diameter of a compression spring from inside one side of the inner diameter to the other side of the inner diameter. (Lalo Show Icon)

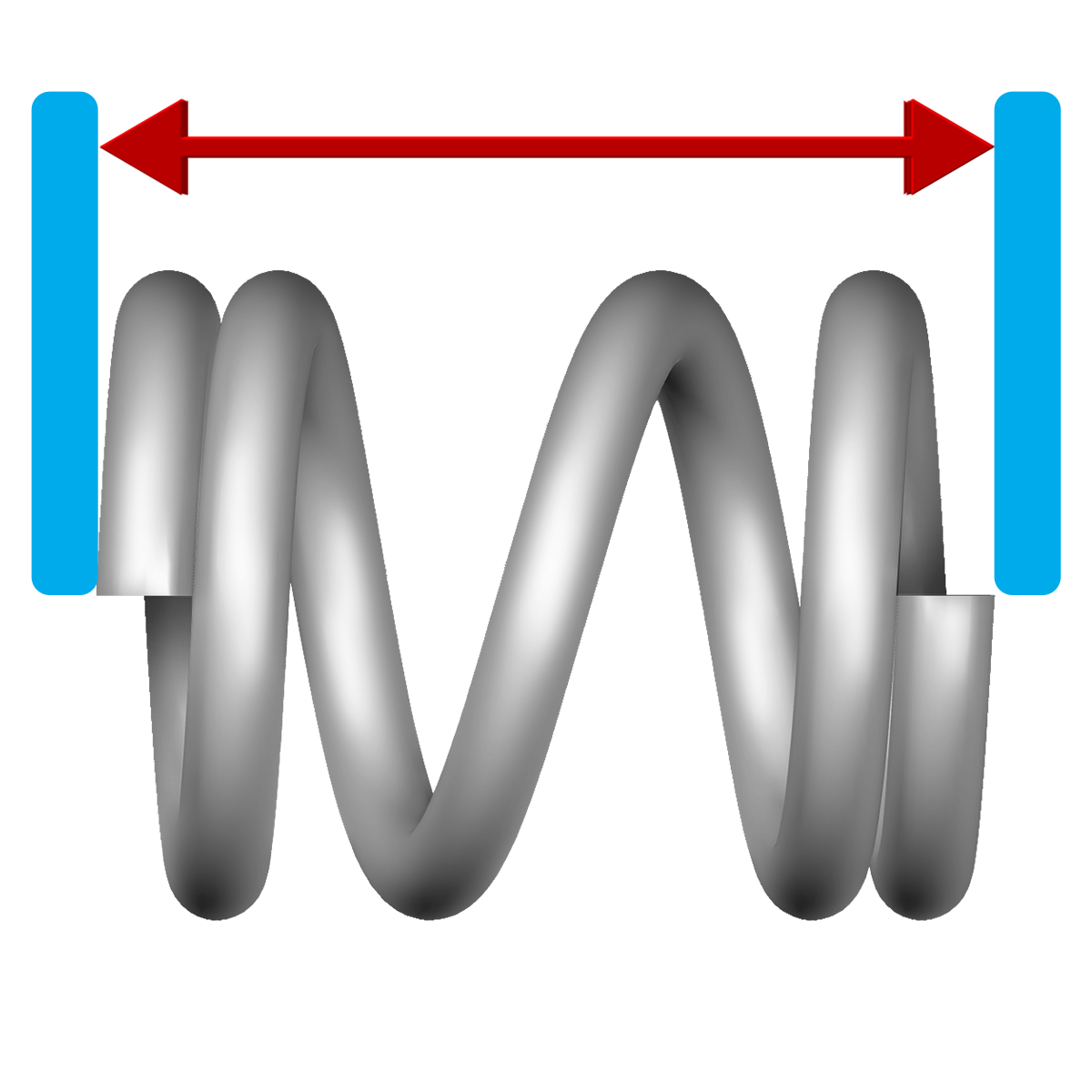

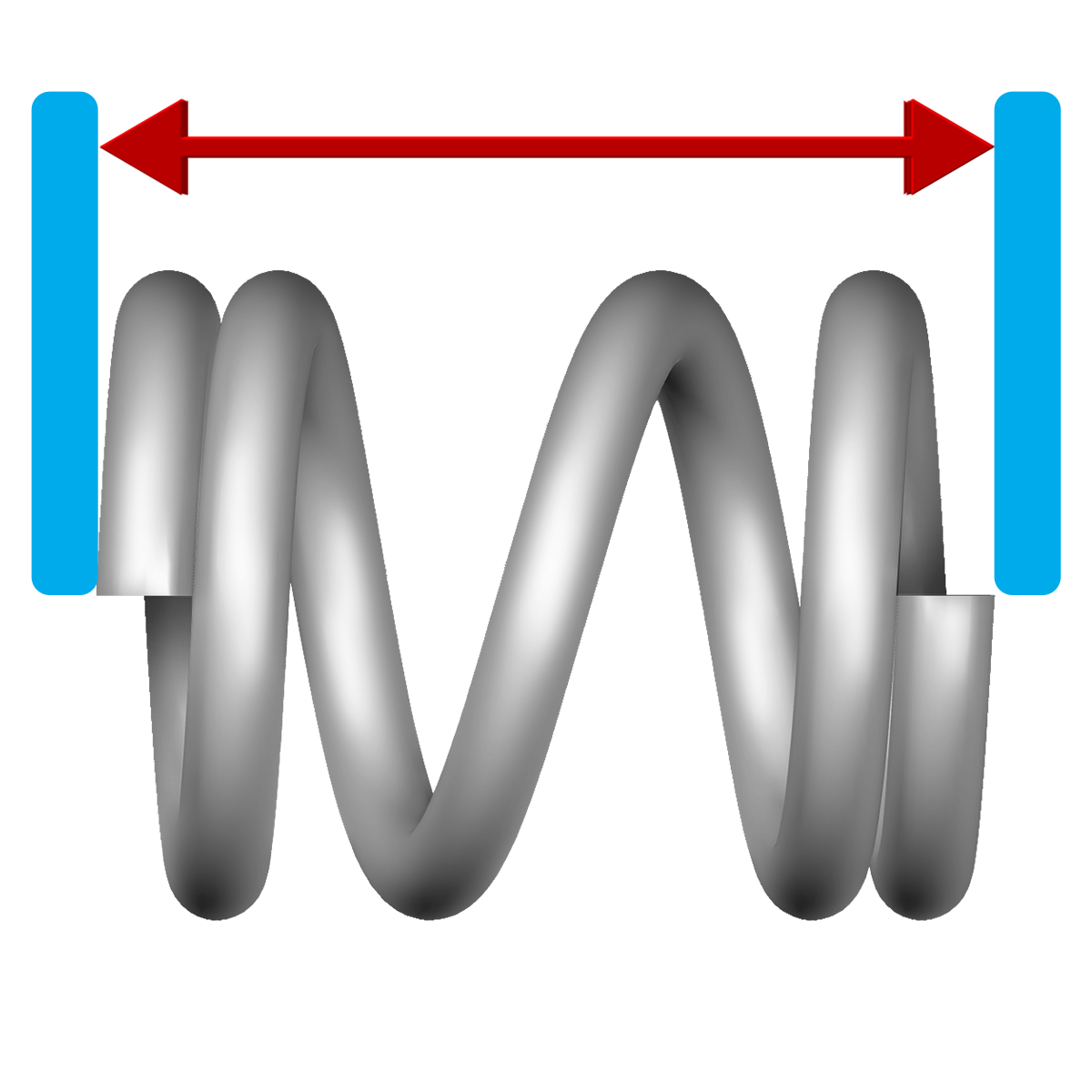

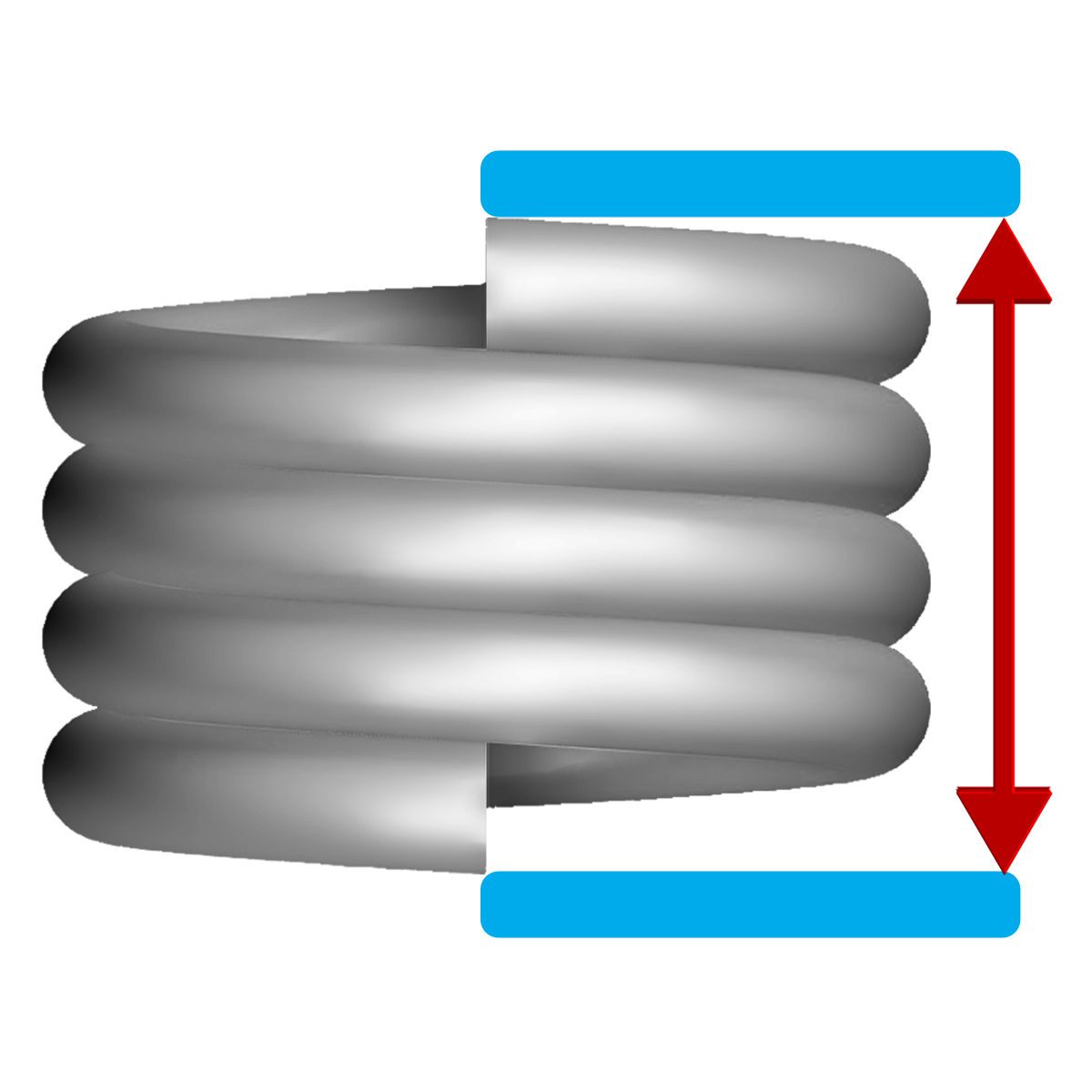

- Free Length: The overall uncompacted length of a compression spring also known as spring length or total overall spring length.

- Total coils: The total amount of circular wound coils that contain space in between a spring's helical coils as well as the coils that have no pitch. Meaning total count of all open or closed helical coils in a compression spring.

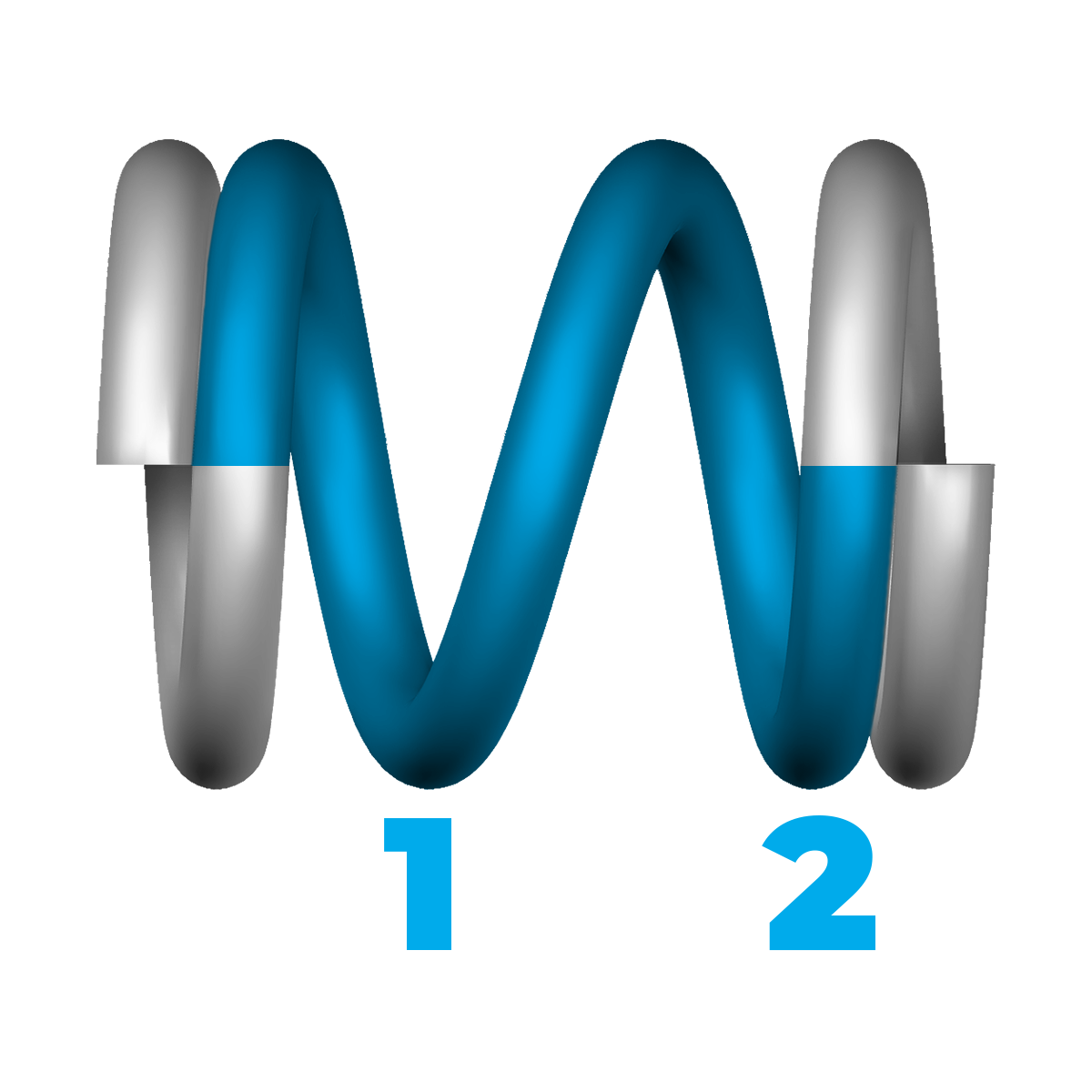

- Active Coils: The amount of circular wound coils that contain space in between a spring's helical coils these coils have pitch meaning these are open coils that exert load and energy when compacted.

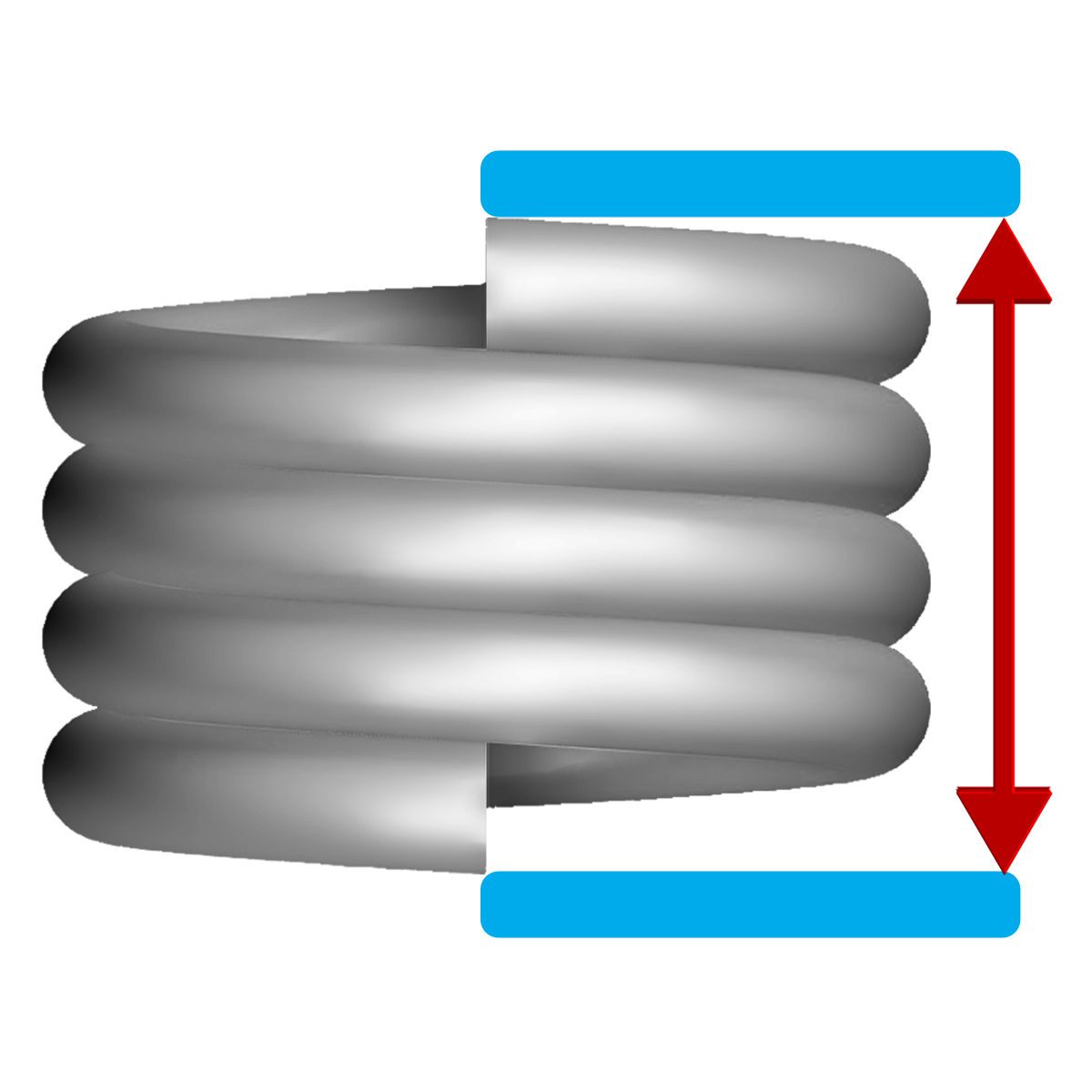

- Solid Height: When all the coils on a compression spring are in contact with each other. Meaning solid coil stacked height the spring cannot compress any further. The absolute maximum compression of a compression spring where all circular coils are in contact.

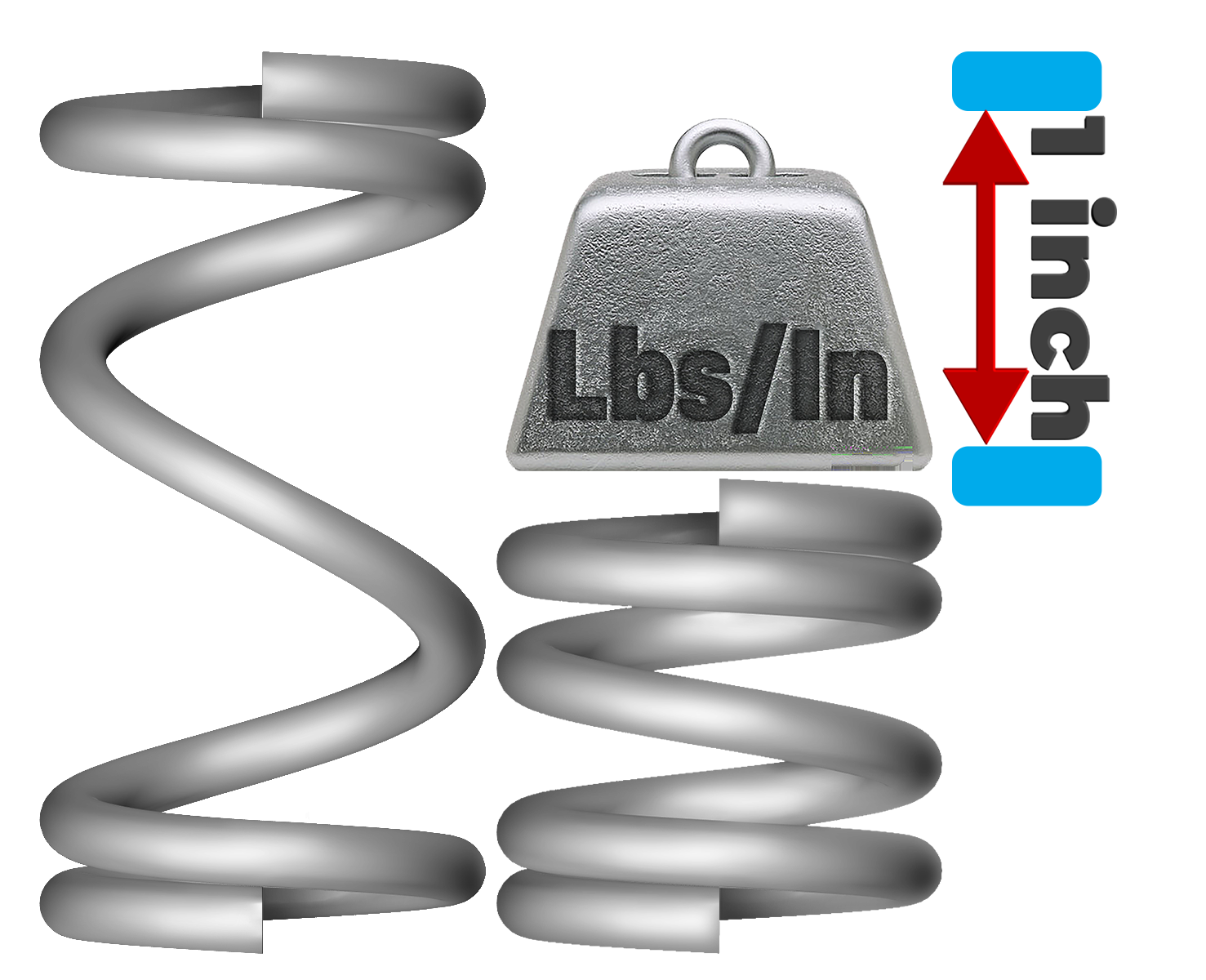

- Compression Spring Constant / Rate Definition: Spring rate k or also known as spring constant is the measurement of a spring’s load in (pounds or newtons) to one unit of deflection in (inch or millimeter). It’s a constant force value that lets you calculate how much load you will require for a specific distance of deflected travel, it also helps you gauge how much compression distance you will accomplish when applying different load forces.

What are Compression Spring End Types?

Choosing the correct end type is critical for certain applications. Here is a list of the more commonly used compression spring end types.

- Closed and Squared Ends: This compression spring end type is good when you have a spring index above 6 or 7 and a slenderness ratio of less than 3.5. Closed and squared ends offer support and diminish the chance of the spring tipping over. If your compression spring is not too long and has a good size outer diameter then you might be ok using closed and squared ends. Check your slenderness ratio to be sure.

- Closed and Ground Ends: Same as closed and squared ends but the first and last coils are ground flat so the spring can stand erect vertically. Closed and ground ends offer a more even flat surface on the ends of the compression spring. More even force and load connection with a horizontal ground flat surface. The favored end type for compression springs with a slenderness ratio greater than 4.

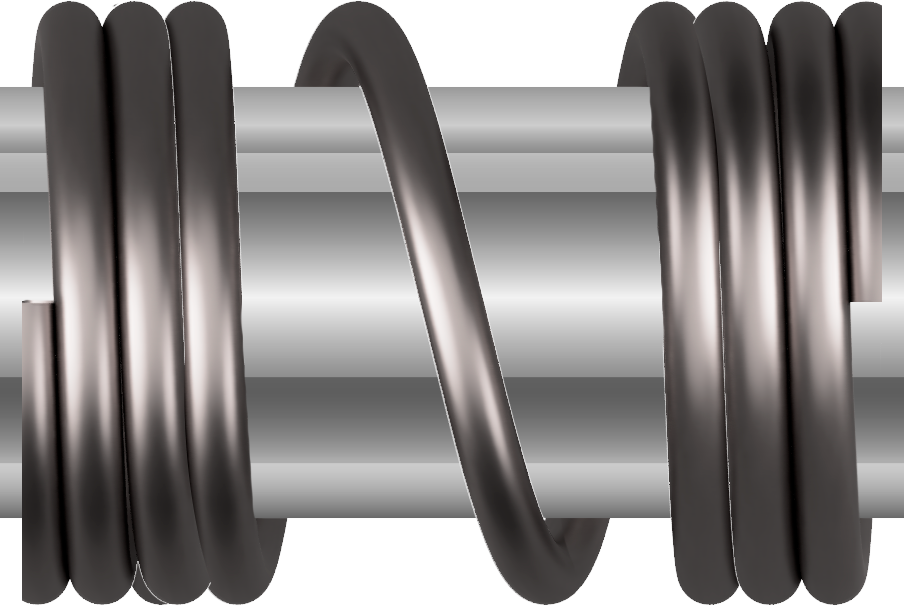

- Open Ends: Compression spring ends that are open and have pitch in all coils meaning all helical coils in the spring do not touch; they are open and have space in between the coils. The benefit of open coils is the spring can travel further since there are no closed coils on the end of the spring thus making the springs solid height shorter to give more distance traveled. An economical solution if you need less solid height and place the compression spring over a shaft or in a hole.

- Double Closed Ends: 2 closed coils on each end of the spring. This end type gives more vertical support. Double closed ends have a larger solid height to take into account.

- Triple or more closed ends: A crossbreed option that offers convenience:

-

- Compression springs with small wire diameters of 0.005 to 0.025 thousands of an inch

- Compression spring that have large indexes above 15 to 30 benefit from more stability

- Compression springs that have fine wire diameters from 0.002 to 0.020 benefit from more stability.

- An option for having multiple closed ends: Multiple closed ends offer the ability to thread a compression spring over a threaded shaft for fixing. Usually 2 or more spring coils are threaded onto a thread. The wire diameter must fit on the thread shaft as well as the spring's inner diameter must fit over the threaded shafts outer diameter for this option to work.

- One or More Closed Ends and Multiple Closed Ends: The advantage of one or more closed ends is that you can experiment with a few or more closed ends on both ends of your spring and see which scenarios work best for you in terms of stability. Being able to thread both ends of your compressing spring onto a threaded bolt offers superior placement of your spring and gives you a long lifespan on your compression springs because they are secure and stable.

- Music Wire (ASTM A228): For applications where durability under high stress and fatigue is paramount, music wire provides an exceptional balance of strength and flexibility. Its widespread use in automotive, industrial, and consumer electronics underscores its versatility and reliability.

- Stainless Steel 302: The choice for environments where corrosion could compromise performance. Its semi non-magnetic and rust-resistant properties make it indispensable in medical, food processing, and marine products, ensuring longevity and safety.

- Hard Drawn (ASTM A227): Offering a more economical solution without sacrificing quality, hard drawn wire is suited for less stressful spring designs and applications where material costs are a concern. Its use spans across various industries, including construction and agriculture.

- Exotic Alloys: For the most challenging environments and applications, Acxess Spring provides options in exotic materials such as Beryllium Copper, Phosphor Bronze, Chrome Silicon and more. These materials are tailored for extreme conditions, ensuring performance where standard materials might fail.

The right finish can significantly extend the life of a spring, especially in challenging environments. Acxess Spring's plating options are designed to enhance both the functional and aesthetic qualities of their springs:

- Zinc Plating: A popular choice for its excellent corrosion resistance and aesthetic appeal, zinc plating is versatile, providing robust protection in a wide array of applications. Finish color is medium bright chrome

- Black Oxide: Offering a matte black finish, this option is sought after for applications where non-reflectivity is required. While providing mild corrosion resistance, its primary benefit lies in its aesthetic appeal.

- Gold Iridite: For really good resistance to corrosion and electrical conductivity, gold iridite is incomparable. You will see its use in electronics, and agriculture.

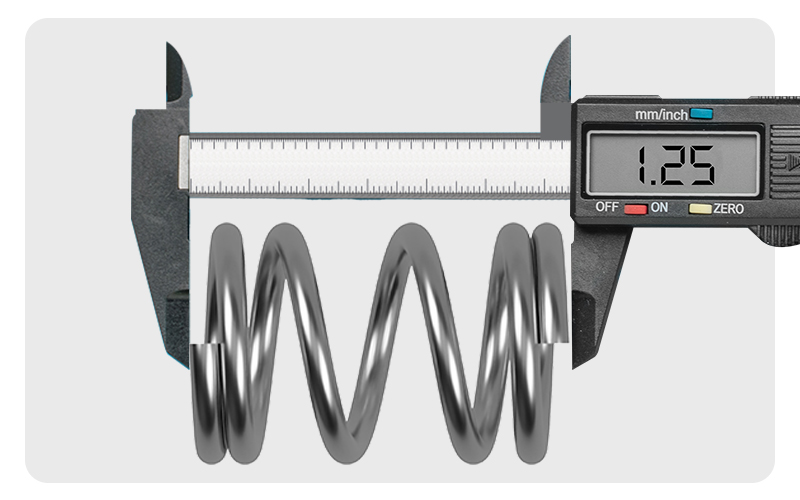

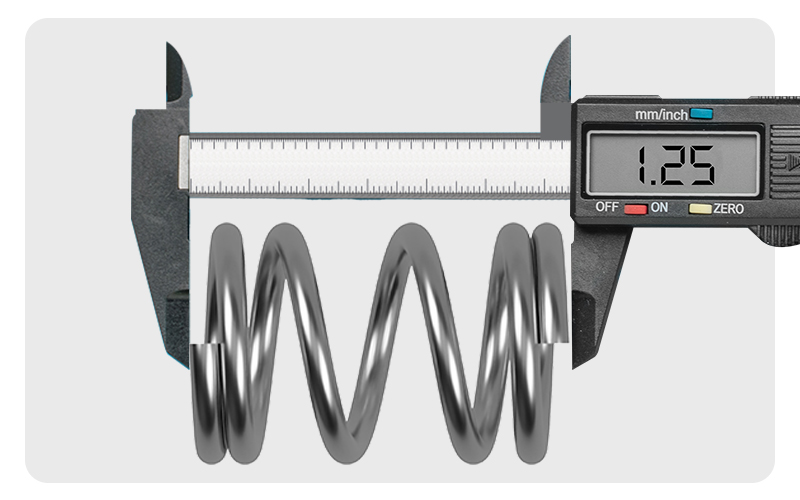

Precisely measuring the specifications of a compression spring is fundamental. Here we show you how to measure your compression spring correctly displaying all the key dimensions of a compression spring:

- Wire Diameter (d): Critical for calculating the spring's strength and flexibility, the wire diameter is measured across the cross-section of a single wire. A precise wire diameter measurement is essential for accurate spring constant calculations. (Lalo Show picture)

- Outer Diameter (OD): With digital or dial calipers to measure the outer diameter at the widest point of the compression spring. (Lalo Show picture)

- Inner Diameter (ID): With digital or dial calipers measure across the inside of the spring. Measuring these specifications correctly are crucial for fitting the compression spring into its operational space without interference. (Lalo Show picture)

- Free Length: The length of the spring when it is not under any load is known as the free length. With digital or dial calipers measure from one end of the spring to the other end of the compression spring putting the spring horizontally into the jaws of the calipers to take a reading. This dimension is important for understanding how much space the spring will occupy in its natural state. (Lalo Show picture)

- Total Coils: Counting the total number of coils is important for calculating the spring rate and understanding the spring's potential compression. Include both active and inactive coils in your count for a comprehensive understanding of the spring's design.

Tips for Accurate Measurement:

- Use Precision Tools: A digital or dial caliper is recommended for the most accurate measurements, especially for wire and coil diameters. Do not use a tape measure!

- Measure in Multiple Places: To account for potential variations, measure diameters at several points along the spring and use the average of these measurements.

- Consider Spring Tolerance: Understand the manufacturer's tolerance specifications, as slight variations in measurements can be within acceptable limits and not affect the spring's performance.

- Blueprints / Spec Sheets: Every one of our 70 Trillion springs comes with precise spec sheets / blueprints that come with all the compression spring tolerances for every compression spring dimension.

Accurate measurement is more than a procedural task; it's a critical component of successful spring application and design. With these guidelines, you can ensure that your spring measurements are precise, laying the foundation for optimal functionality and performance in your projects.

Spring compression calculation is vital for understanding how a spring behaves under load. The basic principle involves knowing the spring's initial free length and subtracting the distance it compresses under load. This calculation requires knowledge of the spring's rate, which defines how much force is needed to compress the spring by a given amount. A simple formula to remember is Compression= Spring Constant (K )/ Load.

Spring compression is crucial in applications where space and functionality intersect, such as in safety locks for children's toys. For a spring with a spring rate of 4.626 lbs/in and subject to a working load of 6.5 lb, the compression can be calculated as:

x= F/ x

x=6.5 lb/ 4.626 lbs/in

X ≈ 1.405inches

This calculation ensures the spring compresses the right amount under load without exceeding its max deflection limit of 2.093 inches of travel, guaranteeing the safety lock engages securely without being overly difficult to operate.

(Lalo Show this OSFT Gif here.)

This example is based on part number: PC047-500-18300-MW-3000-C-N-IN

The rate of a compression spring, or spring constant, is a critical parameter that influences its performance in an application. It's calculated by considering the material's modulus of rigidity, the spring's wire diameter, coil diameter, and the number of active coils. The formula k = Gd^4 ÷ (8D^3 * n) gives a direct measurement of the spring's stiffness, indicating how much force is necessary to compress the spring by a specific amount of distance which is lbs/in or N/mm. Understanding and calculating this compression spring rate is crucial for designers and engineers to ensure that the spring meets the functional requirements of the application.

Calculating the spring constant, especially for specialized applications such as precision equipment triggers, necessitates a thorough understanding of the spring's physical attributes and inherent stiffness. For a spring with these dimensions - an outer diameter of 0.375 inches, a wire diameter of 0.028 inches, and a total of 16 coils - the spring constant gives us insight into its resistance to compression.

The spring constant of 1.510 lbs/in is provided by The Spring Store Part No: PC028-375-16000-MW-2000-CG-N-IN. Typically, the spring constant, or spring rate, (k) might be calculated using known formulas that incorporate material properties and spring geometry. For Music Wire, this would involve factors such as the modulus of elasticity alongside the spring's coil diameter, wire diameter, and number of active coils. Given the specific dimensions:

- Outer Diameter (OD): 0.375 inches

- Wire Diameter (d): 0.028 inches

- Total Coils (N): 16

- Free Length: 2.000 inches

The formula for the spring constant would be like this:

k = Gd^4 ÷ (8D^3 * n)

Where G is the modulus of rigidity for Music Wire, and D is the mean coil diameter (OD - d). This constant is integral for designers to ensure that the spring meets the operational requirements of precision triggers, providing enough resistance to compression without necessitating excessive force.

Through accurate computation of the spring constant, engineers are empowered to tailor the spring's performance for its intended use, ranging from heavy-duty industrial equipment to delicate electronic apparatus. Acxess Spring's Spring Creator 5.0 enhances this task, offering a user-friendly interface for precise spring design and refinement. It utilizes sophisticated calculations to transform engineering concepts into reality. Understanding the calculation behind the spring constant allows engineers to tailor spring specifications precisely to the needs of applications requiring meticulous force management, ensuring both functionality and user satisfaction in the final product.

In practical terms, calculating a spring's load means figuring out the force it needs to handle in its application, from holding up a shelf to cushioning a landing gear's impact. It involves assessing the weight or force the spring will support and ensuring the spring's specifications can accommodate this load without failure. This step is critical in applications across all industries, as it ensures the spring can perform its intended function reliably, under the full range of operational conditions.

When designing a spring for a specific application, such as a mechanical pencil mechanism, calculating the maximum load capacity ensures the spring can endure the operational force without deforming. Given a spring with a rate of 1.510 lbs/in and designed for a max deflection of 1.551 inches, the maximum load it can withstand is calculated as:

Maximum Load=Spring Rate×Max Deflection

Maximum Load= 1.510 lbs/in × 1.551 inches

Maximum Load= 2.342 lbs

This calculation indicates that the spring is suitable for applications where the force does not exceed 1.510 lb, ideal for lightweight mechanisms.

This example is based on part number: PC028-375-16000-MW-2000-CG-IN

(Lalo Show this OSFT Gif here.)

Determining a spring's loaded height is about measuring how much space the spring occupies under load. This measurement is key in applications where space is limited, like within electronic devices or automotive assemblies. To calculate, you subtract the displacement (the amount the spring compresses under load, calculated as Load/ Spring Constant) from the spring's original free length. This ensures that the spring will not only fit in its designated space under load but also operate effectively without interference.

In designing a component where space is at a premium, such as a battery compartment door spring, calculating the spring's load height is essential. The spring in question, with a free length of 0.375 inches and facing a load of 0.600 lbs, needs to compress without bottoming out, ensuring the door closes snugly yet opens easily. Given the spring's rate of 3.072 lbs/in, the spring's compression under load can be calculated as:

x= Distance traveled or compression distance

X = F/k = 0.600 lbs / 3.072 lbs/in ≈ 0.195 inches distance traveled

Thus, the spring's loaded height is its free length minus the compression distance:

Load Height = Free Length − x (distance traveled)= 0.375 inches−0.195inches = 0.180 inches of loaded hight

This load height ensures that the spring will function within the designated space, providing the necessary force without the risk of over-compression.

This example is based on part number: PC014-180-5400-SST-0375-C-N-IN

(Lalo Show this OSFT Gif here.)

The difference between spring load and spring constant lies in their roles in spring design and function. Spring load is about the force the spring needs to support in its application—a variable determined by the specific use case. It's what the spring is designed to handle. The spring constant, however, defines the spring's stiffness—how much force is needed to compress it a certain distance. This property is inherent to the spring's design, based on its material and physical spring dimensions. Understanding this difference is crucial for anyone working with springs, as it influences both the selection of an appropriate spring for the application and the spring's overall performance and longevity.

Understanding the distinction between spring load and spring constant is crucial for applications like a precision instrument's pressure sensor, where both factors play a pivotal role.

Spring Load: This refers to the force the spring is needed to bear, in this case, 1.0037 lbs uses 0.130 inches of travel. It's a critical specification for ensuring that the spring can perform its intended function under the expected operational conditions without exceeding its maximum deflection of 0.231 inches or its maximum load of 1.844 lbs. This ensures that devices like pressure sensors can operate reliably under varying pressures without damaging the spring or sensor mechanism.

Spring Constant: Also known as the spring rate (7.985 lbs/in) as it is measured in lbs/in or N/mm, it quantifies the spring's stiffness at a set distance of travel (deflection). A lower spring constant indicates a softer spring that compresses more easily under load, ideal for sensitive applications requiring fine adjustments, such as in the pressure sensor where precise movements are critical.

This example is based on part number: PC014-094-15500-MW-0470-C-N-IN

(Lalo Show this OSFT Gif here.)

Spring Creator 5.0, developed by Acxess Spring, is more than a tool; it's a cornerstone for precision in spring design engineering. This advanced online spring calculator is designed to bridge the gap between conceptual design and practical application, offering a suite of features that ensure each spring is crafted to meet exacting standards. Spring Creator 1.0 was developed in 2010 and is now on version 5.0 in 2024. Over 14 years and counting of spring design excellence.

- Comprehensive Calculation Capabilities: At the heart of Spring Creator 5.0 are its extensive calculation functions, which cover everything from basic spring constant calculations to more complex analyses involving load deflection and stress distribution. These capabilities allow engineers to refine their designs with an unprecedented level of detail, ensuring the final product performs reliably under the specified conditions.

- Real-Time Visualization and Prototyping: With Spring Creator 5.0, visualization goes hand in hand with calculation. The tool generates immediate, detailed 3D blueprints and 3D Spring CAD models of the designed compression, extension or torsion spring, providing a tangible representation of the end product. This feature is invaluable for spotting potential issues early in the design phase and for communicating design intentions with team members and stakeholders.

- Seamless Integration into Engineering Workflows: Designed to integrate seamlessly into existing engineering workflows, Spring Creator 5.0 supports export options that make it easy to incorporate spring designs into broader 3D CAD environments. This ensures that the springs are not only designed in isolation, but are also perfectly suited to their role within more complex assemblies. Users can download their compression springs in loaded height or distance traveled to ensure proper fit into their product.

- Cost and Efficiency Analysis: Beyond design and material considerations, Spring Creator 5.0 provides insights into the purchase costs associated with different design choices. Every spring design comes with an Instant Spring Quote allowing engineers to manage budget constraints effectively, choosing options that meet both performance requirements and economic realities.

- Global Accessibility and Collaboration: As a web-based tool, Spring Creator 5.0 is accessible from anywhere, facilitating collaboration among distributed teams and enabling efficient design iteration across different locations. This global accessibility ensures that engineering expertise can be applied to custom spring design, regardless of geographic boundaries. Other so-called spring calculator experts only offer old fashioned hard drive spring calculators with user licenses for one computer. We're past that in so many ways.

In summary, Spring Creator 5.0 by Acxess Spring is not just a spring design tool; it's a comprehensive spring design platform that empowers engineers to bring precision, efficiency, and innovation to their spring design projects. With its advanced features, it stands as an essential ally in the creation of custom springs that meet the dynamic demands of modern applications.

With our Online Spring Finder 5.0, specifying your requirements from material type to outer diameters, and different lengths. Finding a compression spring has never been easier. For those seeking precision, our advanced search capabilities and comparison tool aid in making informed spring decisions.

At the top of every web page there is Spring Finder 5.0, for your convenience. You will also find the option to look at the entire stock compression spring catalog through our site. You will also find the option to download our entire stock compression spring catalog in PDF format for your reference and perhaps a better view of what we have to offer.

Dive into our catalog at The Spring Store by Acxess Spring, where over 70 trillion stock and custom compression springs await. Coupled with the Spring Creator 5.0, our resources are designed to support the aspirations of makers, manufacturers, and innovators alike.

Identifying the exact compression spring for your needs is streamlined with Spring Creator 5.0. Whether it's selecting the right stock spring from an extensive inventory of over 70 trillion stock and custom compression springs or crafting the perfect custom solution, this tool ensures precision and efficiency. With its intuitive design, Spring Creator 5.0 guides users through the process of pinpointing specifications, comparing stock options, or engineering a bespoke spring, embodying Acxess Spring's dedication to meeting every unique engineering challenge.